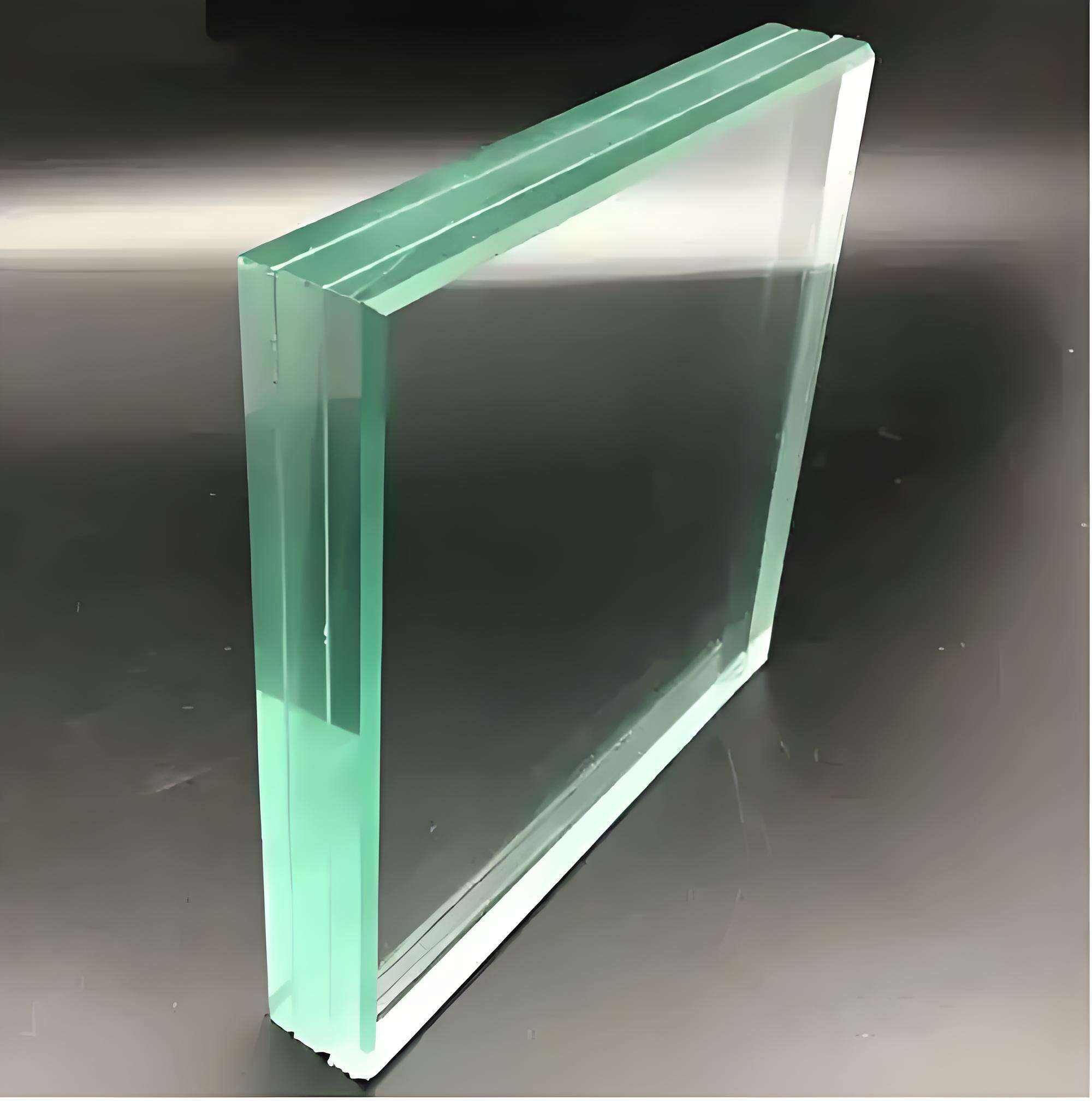

heat tempered glass

Heat tempered glass represents a significant advancement in glass manufacturing technology, engineered through a carefully controlled thermal processing method. This specialized glass undergoes intense heating to approximately 620°C followed by rapid cooling, creating a product that is 4 to 5 times stronger than conventional annealed glass. The process creates a compressed surface layer and tensile core, resulting in exceptional durability and safety features. When broken, heat tempered glass shatters into small, rounded pieces rather than sharp shards, significantly reducing injury risks. This safety glass finds extensive applications in automotive windshields, building facades, shower enclosures, and electronic device screens. The material's enhanced thermal resistance allows it to withstand temperature variations from -70°C to 250°C, making it ideal for extreme environmental conditions. Its versatility extends to various thicknesses, typically ranging from 3mm to 19mm, and it can be customized with different tints and coatings to meet specific requirements. Modern heat tempering processes also incorporate advanced quality control measures, ensuring consistent strength and optical clarity across the entire surface.