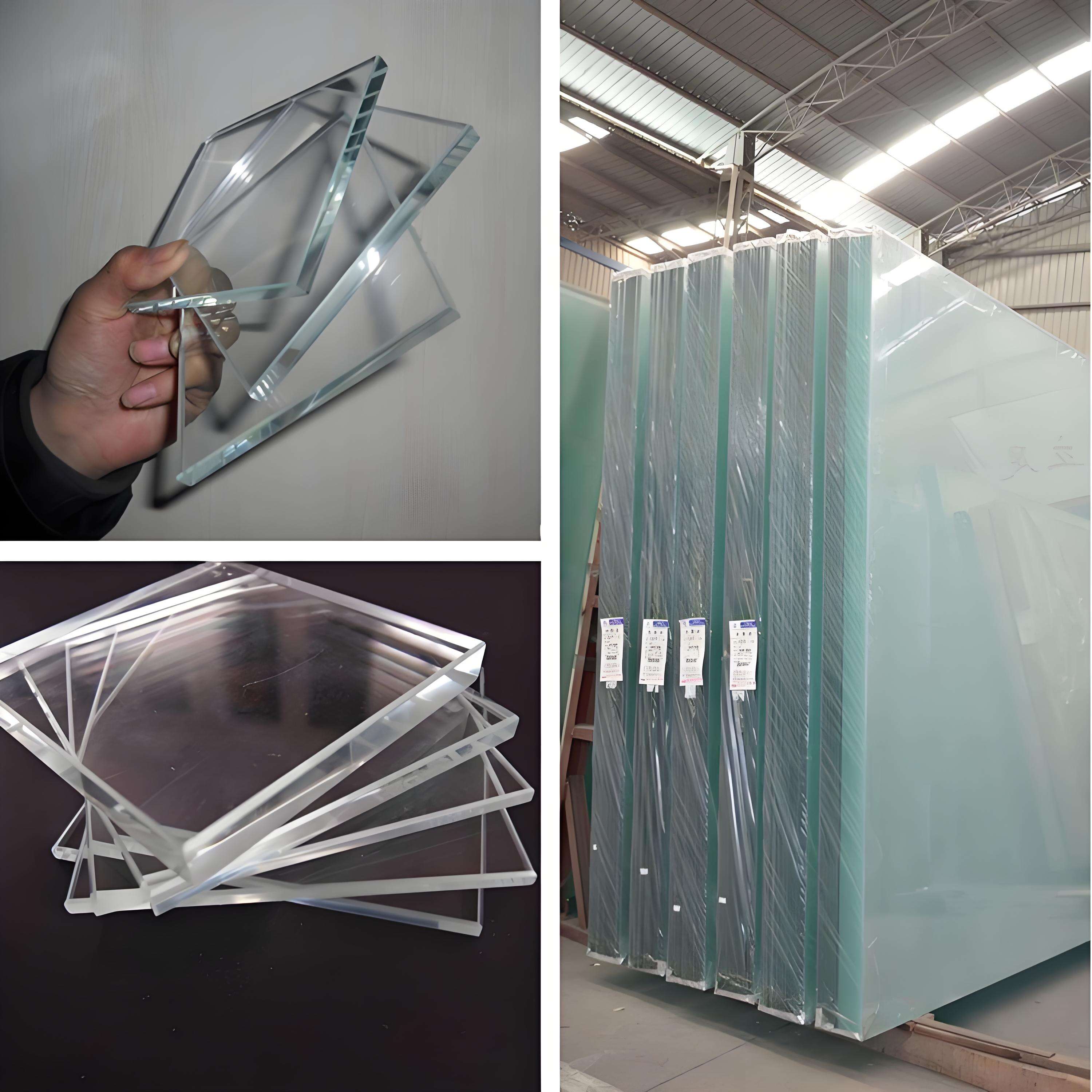

insulated tempered glass

Insulated tempered glass represents a sophisticated advancement in glass technology, combining superior strength with exceptional thermal performance. This specialized glass consists of multiple layers, typically two or more panes of tempered glass separated by a space filled with inert gas such as argon or krypton. The tempering process involves heating the glass to approximately 1,200°F (649°C) and rapidly cooling it, creating a product four to five times stronger than standard glass. The insulating properties come from the sealed air space between the glass panes, which significantly reduces heat transfer. This innovative design makes it particularly effective in maintaining consistent indoor temperatures while providing enhanced safety features. The glass is widely used in commercial buildings, residential construction, and specialized applications where both safety and energy efficiency are paramount. Its versatility allows for various modifications, including low-E coatings for improved solar control and different gas fills for enhanced insulation properties. The manufacturing process ensures that if broken, the glass shatters into small, rounded pieces rather than sharp shards, making it significantly safer than conventional glass. Modern insulated tempered glass units can be customized with various thicknesses, tints, and coating options to meet specific architectural and functional requirements.