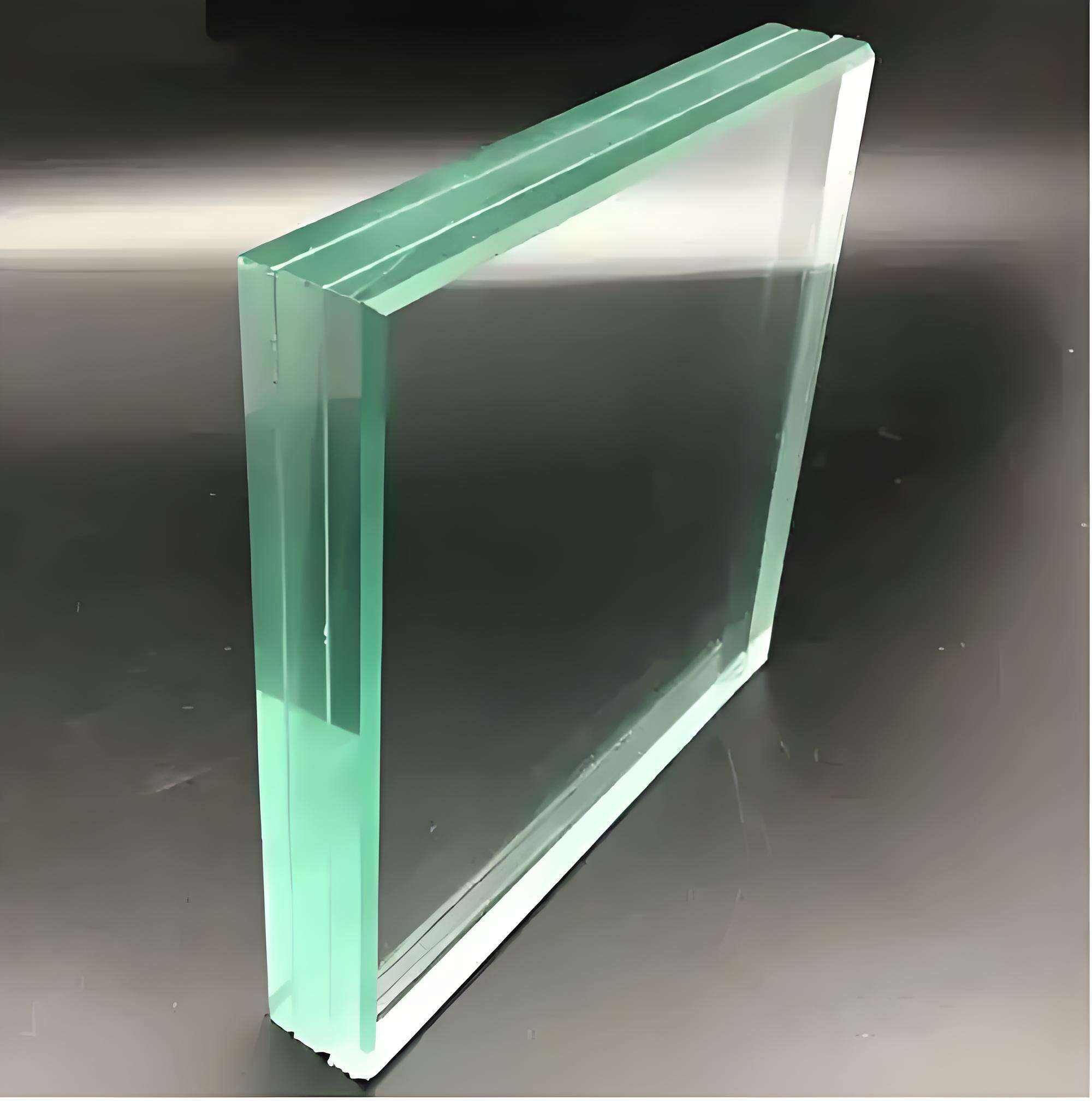

double tempered glass

Double tempered glass represents a significant advancement in glass technology, combining superior strength with enhanced safety features. This innovative glass solution consists of two layers of tempered glass panels, processed through a specialized heat treatment that creates a product four to five times stronger than standard glass. The manufacturing process involves heating the glass to approximately 620 degrees Celsius followed by rapid cooling, creating compression in the glass surface and tension in the interior. This dual-layer construction not only provides increased durability but also offers improved thermal insulation and sound reduction properties. The space between the two tempered glass panels can be filled with inert gas or air, further enhancing its insulating capabilities. When broken, double tempered glass shatters into small, rounded pieces rather than sharp shards, significantly reducing the risk of injury. This safety feature makes it particularly suitable for applications in both residential and commercial settings, including windows, doors, shower enclosures, and architectural facades. The product also offers excellent resistance to thermal stress and sudden temperature changes, making it ideal for various climate conditions and environmental challenges.