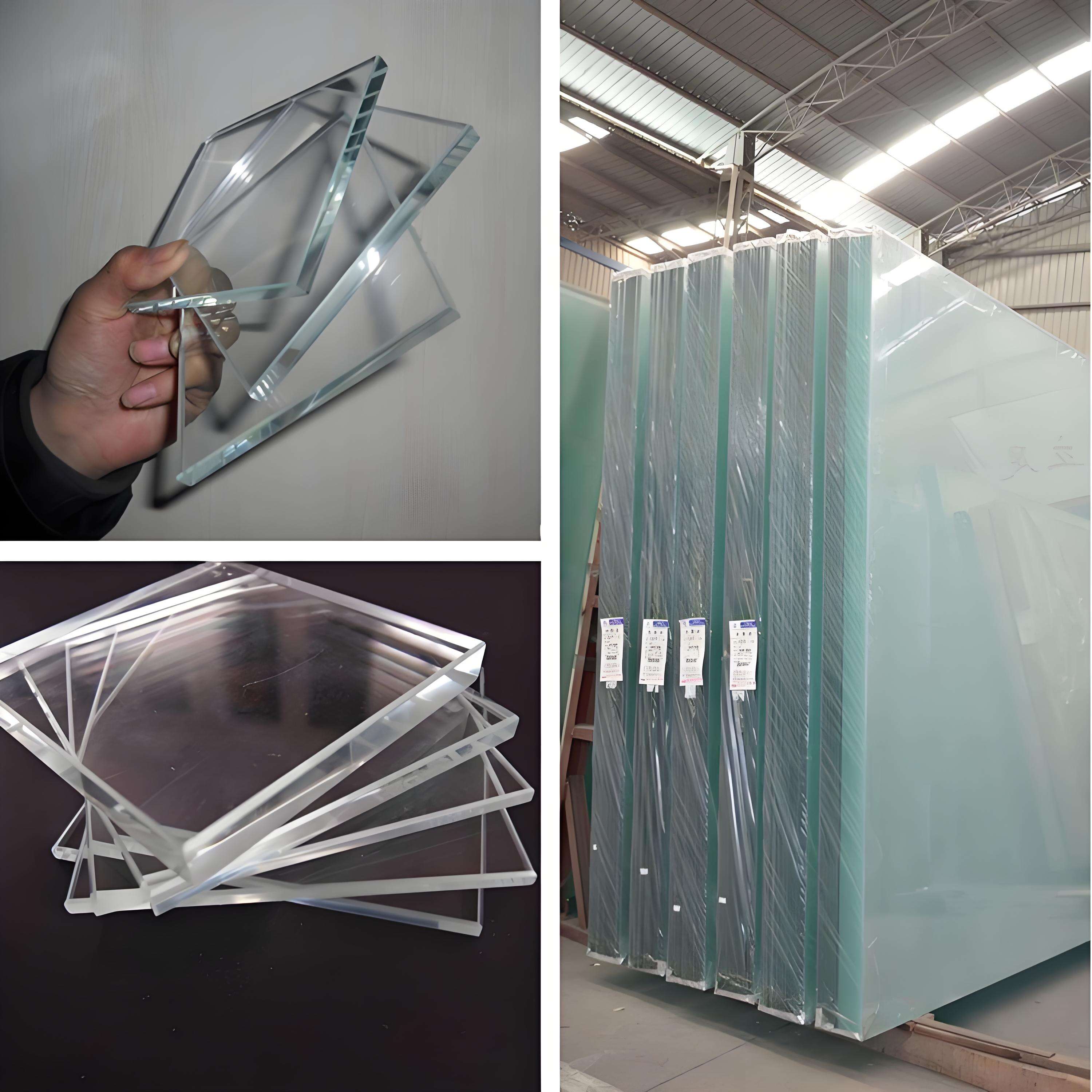

float glass tempered

Float glass tempered is a sophisticated form of safety glass manufactured through a carefully controlled heating and rapid cooling process. This process creates glass that is approximately four to five times stronger than standard annealed glass. The manufacturing begins with high-quality float glass, which is heated to approximately 620°C before being rapidly cooled through a process called quenching. This thermal treatment creates high compression on the glass surface while maintaining tension in the center, resulting in a product that offers exceptional strength and safety characteristics. When broken, tempered glass shatters into small, relatively harmless pieces rather than sharp, dangerous shards. This safety feature has made it an indispensable material in modern construction and automotive applications. The glass maintains excellent optical clarity while providing enhanced thermal resistance, capable of withstanding temperature differences up to 200°C. It's particularly notable for its versatility in various applications, from architectural glazing to automotive windows, shower enclosures, and mobile device screens. The tempering process also improves the glass's resistance to mechanical stress and thermal shock, making it ideal for demanding environments.