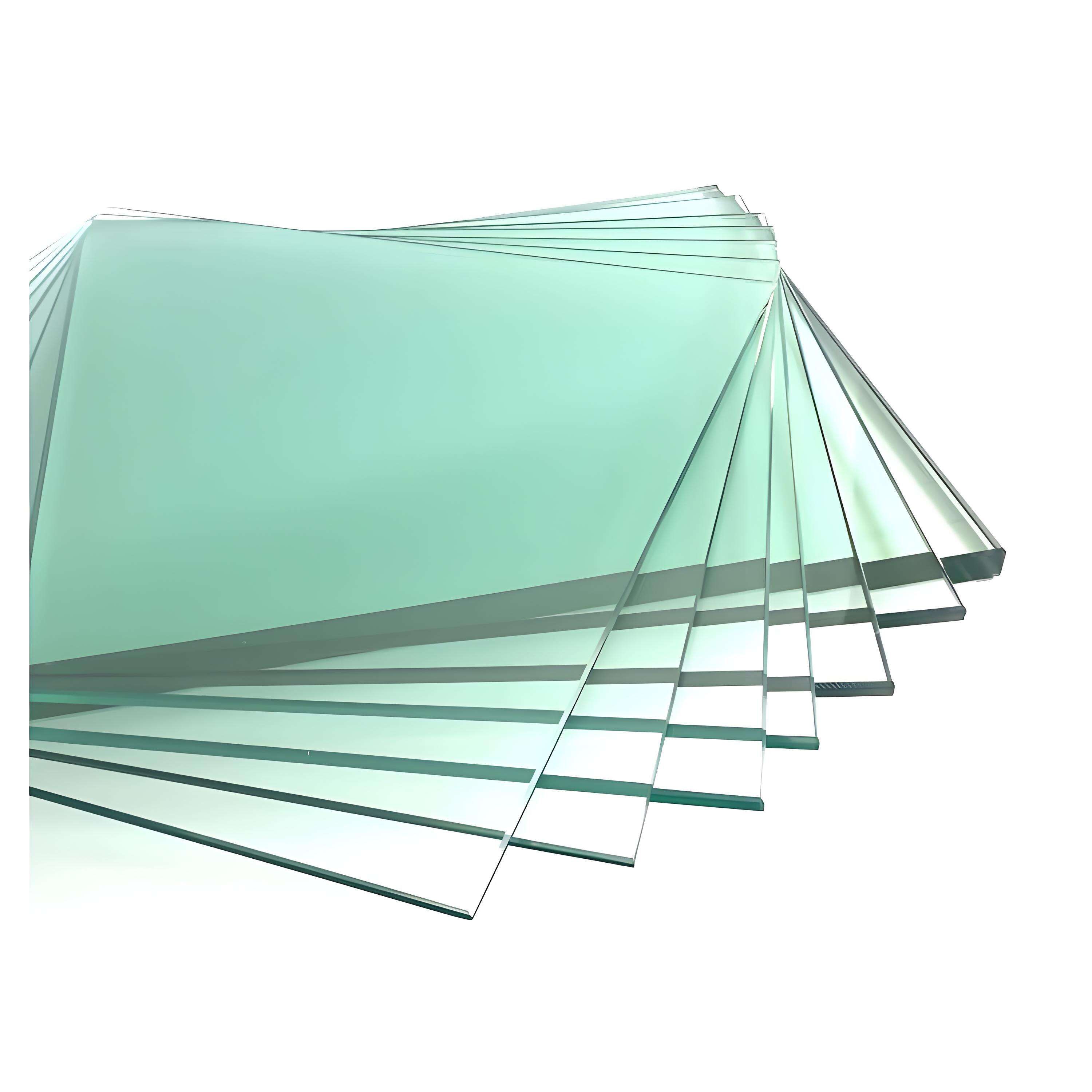

plain float glass

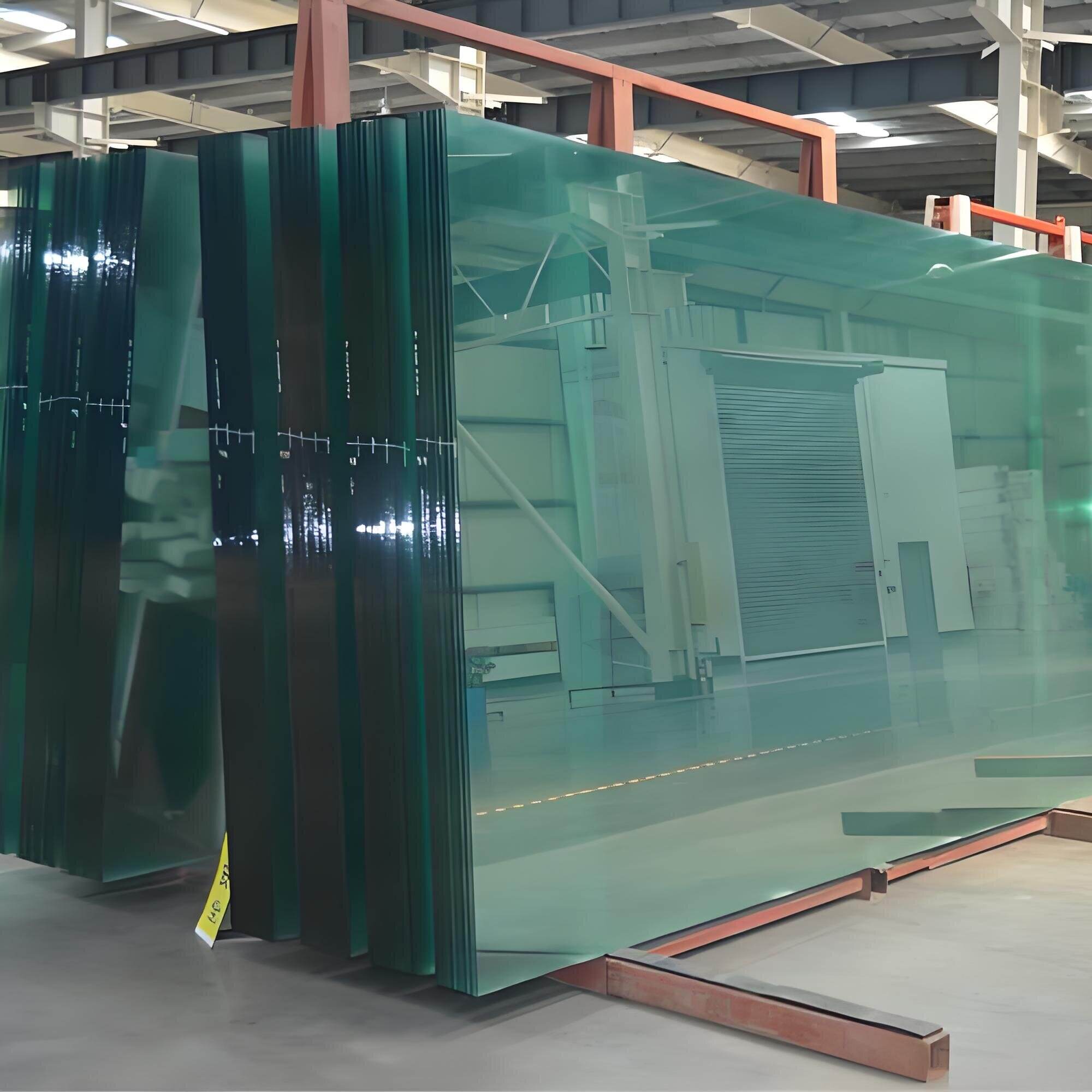

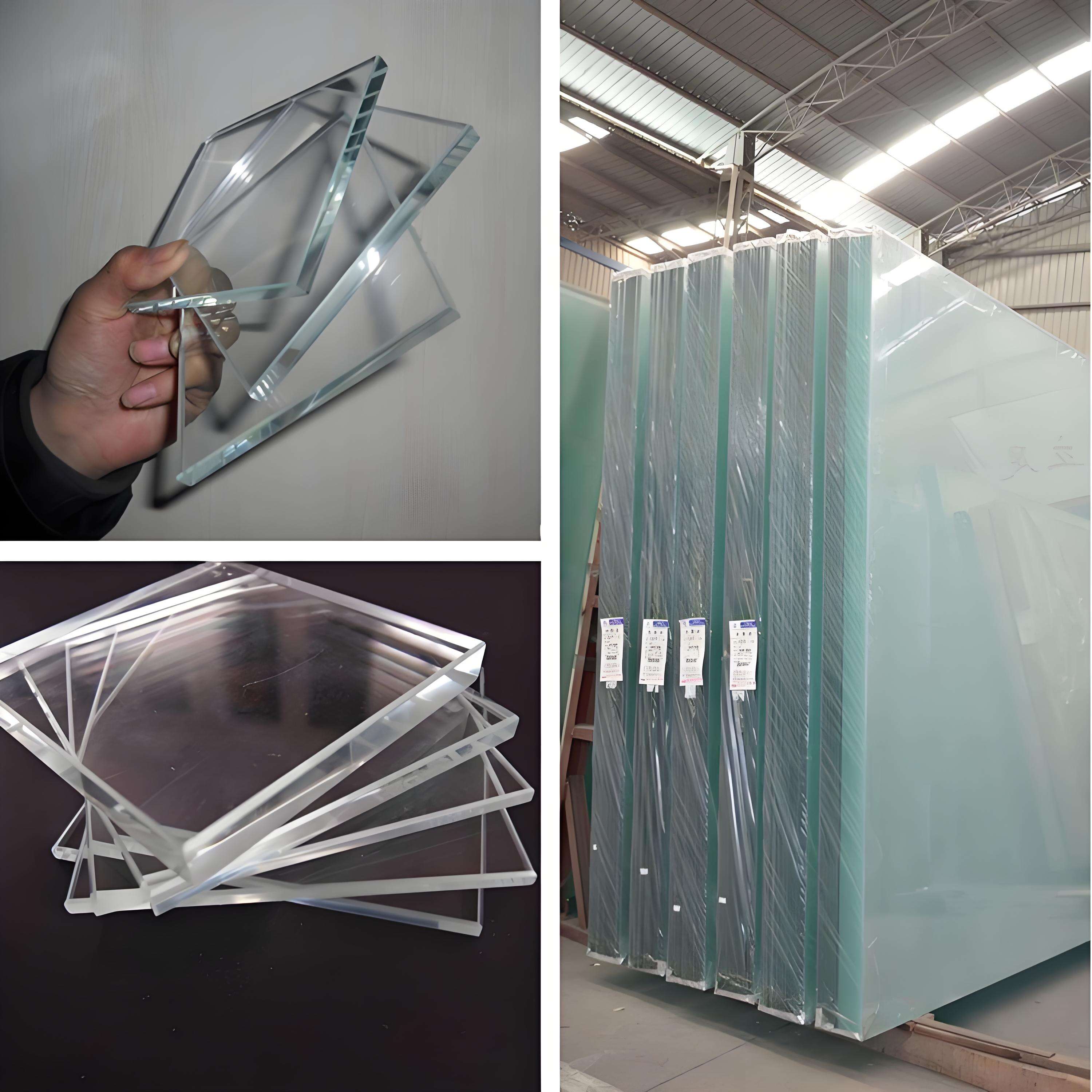

Plain float glass is a fundamental architectural and industrial material manufactured through an innovative floating process where molten glass is poured onto a bed of molten tin. This revolutionary technique, developed in the 1950s, produces perfectly flat, extremely clear glass with consistent thickness and superior optical qualities. The process involves carefully controlled cooling that prevents distortions and ensures uniformity throughout the sheet. This type of glass typically ranges from 2mm to 19mm in thickness and offers exceptional transparency with a visible light transmission of up to 90%. The material's smooth surface and remarkable clarity make it an ideal base product for various glass processing applications. Plain float glass serves as the foundation for numerous glass products, including tempered glass, laminated glass, and insulated glass units. Its versatility allows for applications in construction, automotive manufacturing, solar panels, and interior design. The material's inherent properties provide natural UV protection and consistent optical quality, making it suitable for windows, doors, facades, and display purposes. In modern architecture, plain float glass has become indispensable due to its perfect flatness and distortion-free characteristics, enabling architects and designers to achieve both functional and aesthetic objectives in their projects.