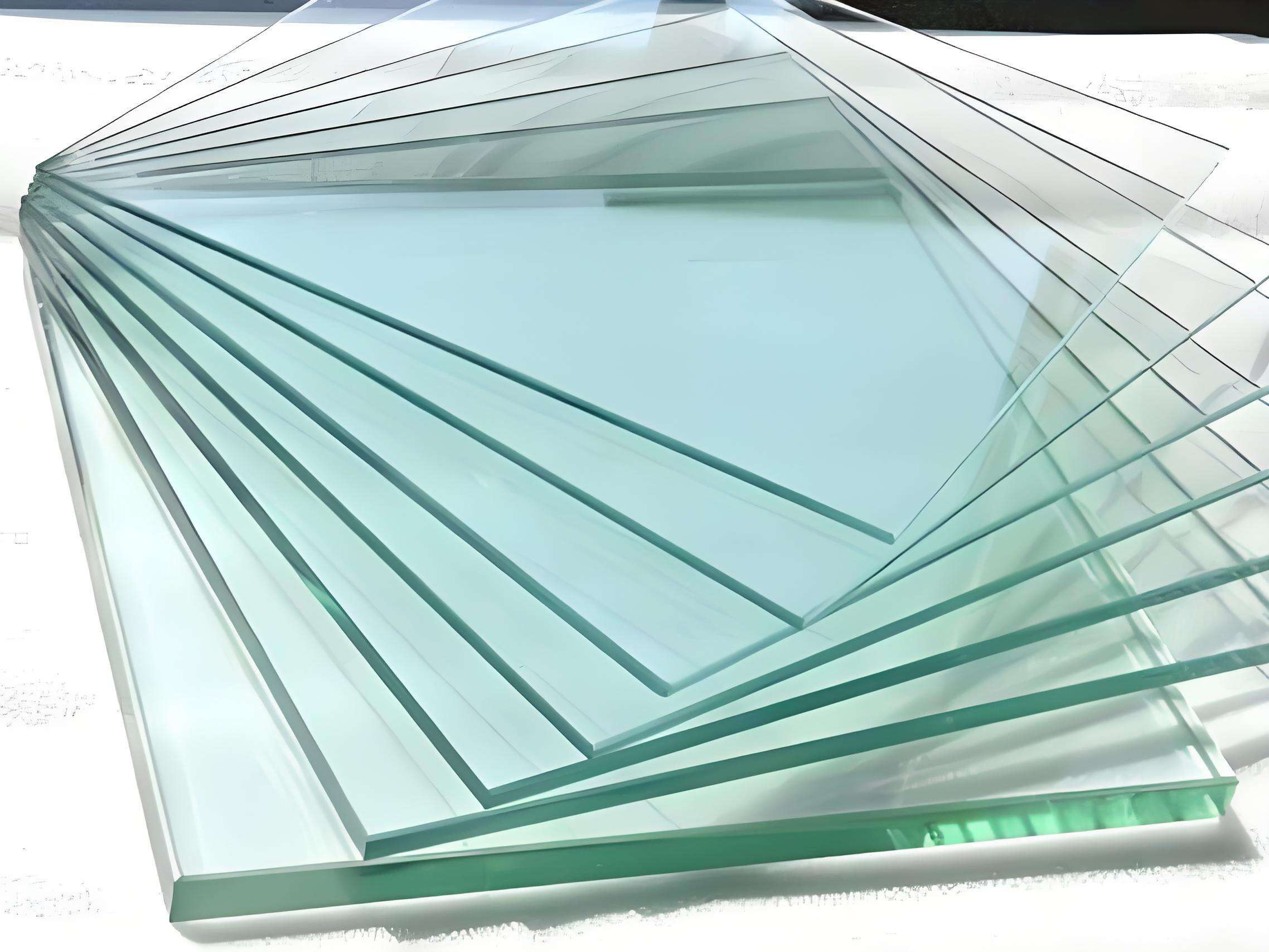

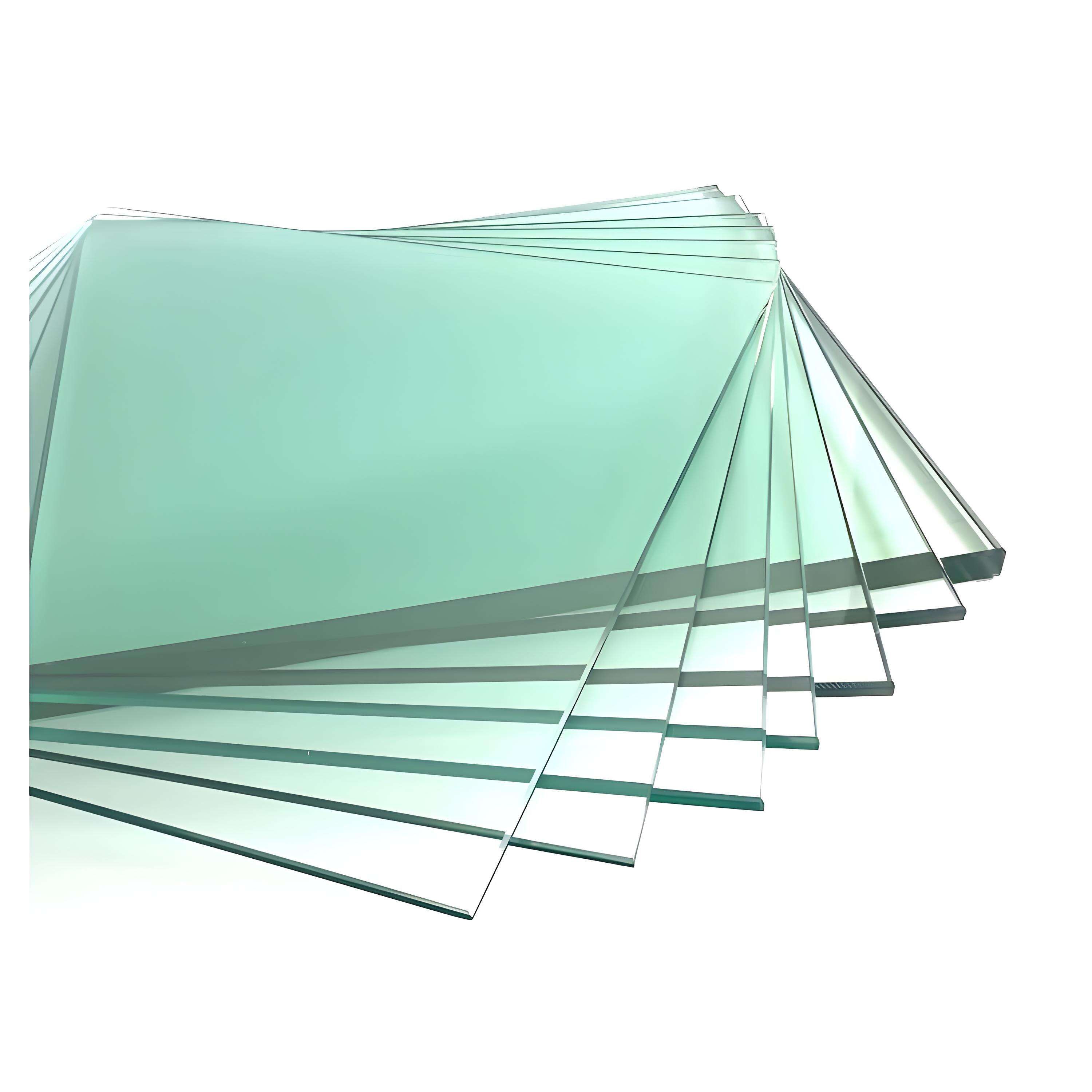

laminated float glass

Laminated float glass represents a significant advancement in glass technology, combining durability with enhanced safety features. This specialized glass consists of two or more layers of float glass bonded together with a tough polyvinyl butyral (PVB) interlayer. The manufacturing process begins with high-quality float glass sheets, which undergo rigorous cleaning before the PVB interlayer is inserted between them. The assembly is then heated and pressed to create a permanent bond, resulting in a single, robust piece of safety glass. The float glass layers provide the structural integrity and optical clarity, while the PVB interlayer serves multiple functions. It acts as an adhesive to hold the glass together upon impact, prevents glass fragments from scattering if broken, and provides additional benefits such as sound insulation and UV protection. The versatility of laminated float glass makes it ideal for numerous applications, from architectural uses in windows and facades to automotive windshields and security installations. Its thickness can be customized according to specific requirements, typically ranging from 6.38mm to 12.76mm for standard applications, with special configurations available for high-security needs.