Modern architecture demands materials that combine exceptional clarity with superior performance, and low iron glass has emerged as the premium choice for applications requiring crystal-clear transparency. Unlike standard float glass, which contains natural iron impurities that create a greenish tint, low iron glass undergoes specialized manufacturing processes to remove these impurities, resulting in unparalleled optical clarity. This ultra-clear glass solution has revolutionized industries ranging from luxury retail displays to high-end architectural facades, where visual perfection is non-negotiable.

The manufacturing excellence behind low iron glass involves carefully controlled raw material selection and advanced melting techniques that minimize iron oxide content to less than 0.01%. This meticulous process creates glass with exceptional light transmission properties, allowing up to 92% of visible light to pass through compared to the 83-85% transmission rate of conventional glass. The result is a material that offers true color representation and eliminates the green edge effect commonly associated with standard glass products.

Superior Optical Properties and Light Transmission

Enhanced Clarity Through Advanced Manufacturing

The exceptional clarity of low iron glass stems from its ultra-low iron content, which dramatically reduces the absorption of light wavelengths that typically cause color distortion. Standard float glass contains approximately 0.1% iron oxide, which creates the characteristic green tint visible along glass edges. In contrast, low iron glass maintains iron oxide levels below 0.01%, virtually eliminating color interference and allowing natural light to pass through with minimal alteration.

This enhanced light transmission capability makes low iron glass invaluable for applications where color accuracy is critical. Museums, art galleries, and high-end retail environments rely on this material to ensure that displayed items appear in their true colors under various lighting conditions. The glass acts as an invisible barrier, allowing viewers to experience artwork, merchandise, or architectural features without the visual distortion that standard glass introduces.

Color Neutrality and Edge Clarity

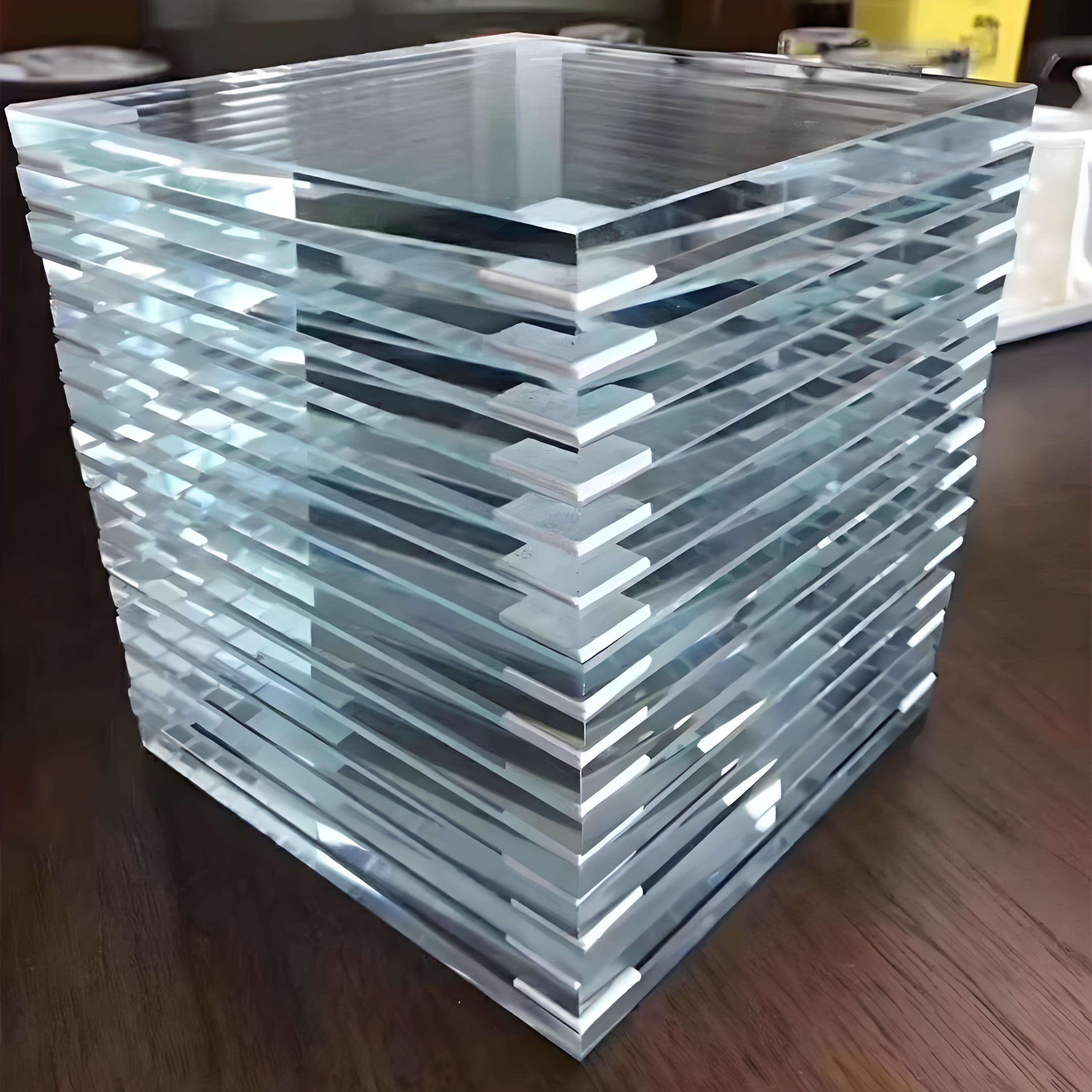

One of the most noticeable advantages of low iron glass is its neutral color profile, particularly visible when viewing glass edges. While conventional glass displays a pronounced green tint along its edges, low iron glass maintains crystal-clear transparency even in thick sections. This property becomes especially important in applications involving laminated glass assemblies or thick glass panels where edge visibility is prominent.

The color neutrality of low iron glass ensures consistent visual appearance across different thicknesses and configurations. Whether used in 3mm sheets for delicate applications or 19mm panels for structural glazing, the material maintains its crystal-clear appearance without the progressive green tinting that affects standard glass as thickness increases. This consistency allows architects and designers to specify uniform appearance across complex glazing systems.

Applications in Modern Architecture and Design

Luxury Retail and Commercial Displays

The retail industry has embraced low iron glass as the standard for premium storefronts and display cases. High-end jewelry stores, luxury boutiques, and flagship retail locations utilize this material to create seamless visual connections between interior and exterior spaces. The enhanced clarity allows merchandise to be displayed with maximum visual impact, eliminating the color cast that can diminish the perceived value of luxury goods.

Commercial display applications benefit significantly from the superior light transmission properties of low iron glass. Trade show exhibits, museum displays, and gallery installations require materials that preserve the true appearance of displayed items under various lighting conditions. The neutral color profile ensures that artificial lighting systems perform optimally, without compensation needed for glass-induced color shifts.

Architectural Glazing and Facade Systems

Contemporary architectural design increasingly favors expansive glazing systems that maximize natural light while maintaining visual connections to exterior environments. Low iron glass enables architects to achieve these objectives without compromising optical clarity. Large-scale glazing installations using this material create virtually invisible barriers that preserve unobstructed views while providing weather protection and thermal control.

Curtain wall systems and structural glazing assemblies benefit from the consistent optical properties of low iron glass across multiple panels. The material's ability to maintain clarity in various thicknesses allows designers to create complex glazing geometries without visual inconsistencies. From sleek office towers to residential high-rises, low iron glass contributes to the seamless integration of interior and exterior spaces that defines contemporary architecture.

Technical Specifications and Performance Characteristics

Physical Properties and Durability

Beyond its optical advantages, low iron glass maintains all the structural properties that make float glass suitable for demanding architectural applications. The material exhibits identical strength characteristics to conventional glass while offering enhanced thermal performance due to its improved light transmission. This combination allows low iron glass to function effectively in both monolithic and laminated configurations across temperature ranges typical of commercial and residential environments.

The manufacturing process for low iron glass incorporates quality control measures that ensure consistent thickness tolerances and surface quality. Available in standard thicknesses ranging from 2mm to 19mm, the material can be processed using conventional glass fabrication techniques including tempering, laminating, and insulated glass unit assembly. This compatibility with existing manufacturing infrastructure makes low iron glass a practical upgrade for projects requiring superior optical performance.

Thermal and Energy Performance

The enhanced light transmission of low iron glass contributes to improved building energy performance by maximizing passive solar gain during heating seasons. The material's ability to transmit up to 92% of visible light reduces the need for artificial lighting during daylight hours, contributing to overall energy efficiency. When combined with appropriate glazing systems and building orientation, low iron glass can significantly reduce lighting energy consumption in commercial and residential applications.

Thermal processing of low iron glass produces tempered versions with enhanced safety characteristics while maintaining optical clarity. Tempered low iron glass meets safety glazing requirements for commercial applications while preserving the material's superior light transmission properties. The combination of safety performance and optical excellence makes this material ideal for floor-to-ceiling glazing systems in high-traffic commercial environments.

Manufacturing Excellence and Quality Assurance

Advanced Production Techniques

The production of high-quality low iron glass requires sophisticated manufacturing processes that begin with carefully selected raw materials. Silica sand used in low iron glass production undergoes extensive purification to remove iron-bearing minerals that would compromise optical clarity. The melting process utilizes specialized furnace designs and atmospheres that prevent iron contamination while ensuring complete homogenization of the glass composition.

Quality control measures throughout the manufacturing process ensure consistent optical properties across production runs. Spectrophotometric analysis verifies light transmission characteristics, while visual inspection confirms the absence of optical defects that could compromise performance. These stringent quality standards result in low iron glass products that meet the demanding requirements of architectural and specialty glazing applications.

Customization and Processing Capabilities

Modern low iron glass manufacturing facilities offer extensive customization options to meet specific project requirements. Edge polishing, hole drilling, and custom cutting services allow the material to be precisely fabricated for complex architectural applications. Specialty coatings can be applied to low iron glass substrates to enhance performance characteristics while preserving optical clarity.

The compatibility of low iron glass with various processing techniques enables its use in advanced glazing systems including structural glazing, point-fixed systems, and curved installations. Heat bending capabilities allow the creation of curved low iron glass panels that maintain optical consistency across complex geometries. These processing capabilities expand the design possibilities for architects working with premium glazing materials.

Economic Considerations and Value Proposition

Cost-Benefit Analysis for Premium Applications

While low iron glass commands a premium price compared to standard float glass, the material delivers significant value in applications where optical performance is critical. The enhanced clarity eliminates the need for artificial lighting compensation in display applications, potentially reducing long-term operational costs. For luxury retail environments, the improved product presentation capabilities can translate directly into increased sales and brand perception benefits.

Architectural applications benefit from the long-term performance advantages of low iron glass, including reduced maintenance requirements and consistent appearance over time. The material's resistance to optical degradation ensures that glazing systems maintain their intended appearance throughout the building's service life. This durability factor contributes to the overall value proposition, particularly in high-profile commercial and institutional projects.

Market Applications and Growth Sectors

The demand for low iron glass continues to grow across multiple market segments, driven by increasing emphasis on design quality and energy performance. Solar panel manufacturers utilize low iron glass for improved energy conversion efficiency, while the electronics industry relies on the material for display applications requiring superior optical clarity. The automotive sector has also embraced low iron glass for luxury vehicle glazing systems.

Emerging applications in smart building technologies and advanced glazing systems are creating new opportunities for low iron glass utilization. Integration with electrochromic coatings and smart glass technologies requires the optical clarity that only low iron substrates can provide. These technological developments ensure continued market expansion for premium glass products in architectural and specialty applications.

FAQ

What makes low iron glass different from regular float glass?

Low iron glass contains significantly less iron oxide (less than 0.01%) compared to standard float glass (approximately 0.1%), which eliminates the greenish tint and allows up to 92% light transmission versus 83-85% for conventional glass. This results in crystal-clear transparency and true color representation without the green edge effect common in standard glass.

Can low iron glass be tempered and laminated like regular glass?

Yes, low iron glass can be processed using all standard glass fabrication techniques including tempering, laminating, and insulated glass unit assembly. The material maintains its superior optical properties throughout these processes while achieving the same safety and performance characteristics as processed conventional glass.

Is low iron glass suitable for energy-efficient building designs?

Absolutely. The enhanced light transmission of low iron glass (up to 92%) maximizes passive solar gain and reduces artificial lighting requirements, contributing to overall building energy efficiency. When properly integrated into glazing systems, it can significantly reduce lighting energy consumption while maintaining thermal performance requirements.

What thickness options are available for low iron glass?

Low iron glass is typically available in standard architectural thicknesses ranging from 2mm to 19mm, with consistent optical clarity maintained across all thickness options. Unlike standard glass which shows increased green tinting with greater thickness, low iron glass preserves its crystal-clear appearance regardless of panel thickness.