Understanding the Sound-Blocking Properties of Modern Glass Solutions

When it comes to creating a peaceful indoor environment, insulating glass has emerged as a revolutionary solution that goes beyond just thermal efficiency. While many property owners initially consider insulating glass for its energy-saving benefits, its exceptional noise reduction capabilities are increasingly becoming a primary reason for installation. In today's fast-paced urban environments, where traffic, construction, and city noise can significantly impact our quality of life, the role of effective sound insulation cannot be overstated.

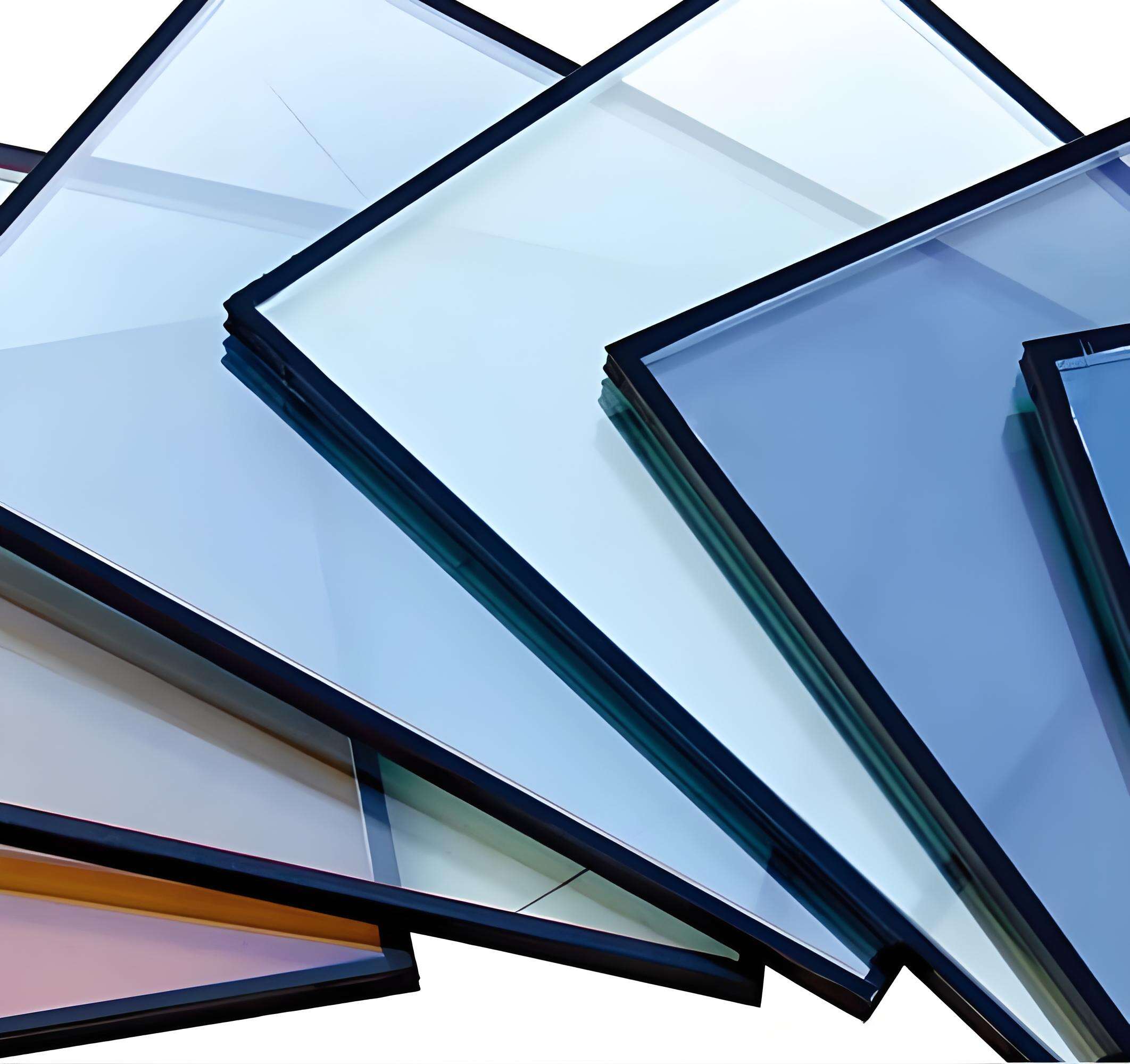

Modern insulating glass units consist of multiple panes separated by spacers and filled with inert gases, creating a sophisticated barrier against both thermal transfer and sound transmission. This innovative design has transformed how we approach acoustic comfort in our living and working spaces, making it possible to enjoy tranquil interiors even in the busiest metropolitan areas.

The Science Behind Acoustic Performance

How Insulating Glass Blocks Sound Waves

The effectiveness of insulating glass in reducing noise lies in its multi-layered construction. Sound waves, when encountering multiple barriers of different densities, lose energy as they attempt to pass through. The air or gas-filled space between glass panes acts as an additional obstacle, forcing sound waves to convert some of their energy into heat, thereby reducing their intensity before reaching the interior.

When sound waves hit insulating glass, they must traverse through the first pane, then the gas-filled cavity, and finally the second pane. Each transition between materials causes the sound wave to lose strength, resulting in significantly reduced noise levels inside the building. The varying thicknesses of glass panes can also be engineered to target specific sound frequencies, making the system even more effective.

The Role of Gas Fill and Spacing

The space between glass panes in insulating units is typically filled with gases like argon or krypton, which are denser than air. This increased density not only improves thermal insulation but also enhances sound dampening properties. The width of this gas-filled space is crucial - optimal acoustic performance usually requires wider gaps than those needed for thermal insulation alone.

Research has shown that varying the spacing between panes can help target different sound frequencies more effectively. Wider spaces generally perform better against low-frequency sounds like traffic or aircraft noise, while maintaining effectiveness against higher-frequency sounds as well.

Performance Metrics and Standards

Sound Transmission Class (STC) Ratings

Insulating glass units are evaluated using Sound Transmission Class (STC) ratings, which measure their ability to block airborne sound transmission. Higher STC ratings indicate better sound isolation properties. Standard single-pane windows typically have STC ratings between 26-28, while quality insulating glass units can achieve ratings of 35 or higher, representing a significant improvement in noise reduction.

The configuration of insulating glass can be customized to achieve specific STC ratings based on project requirements. Factors such as glass thickness, spacing, and the use of laminated glass can all be adjusted to optimize acoustic performance while maintaining other desired properties like thermal efficiency and visual clarity.

Real-World Performance Measurements

In practical applications, insulating glass has demonstrated impressive noise reduction capabilities. Field tests have shown that properly installed insulating glass units can reduce external noise levels by up to 40 decibels, making them highly effective in creating quiet indoor environments. This reduction can make the difference between clearly hearing street traffic and barely noticing it.

Laboratory testing under controlled conditions provides even more detailed insights into the performance of different insulating glass configurations. These tests help manufacturers optimize their products for specific applications and allow architects to make informed decisions when selecting glass solutions for their projects.

Design Considerations and Installation

Optimizing Frame Selection

The effectiveness of insulating glass in noise reduction depends significantly on the window frame system in which it's installed. High-quality frames with proper sealing are essential to prevent sound leakage around the edges of the glass unit. Modern frame materials like vinyl and fiberglass offer excellent acoustic properties while maintaining thermal efficiency.

Professional installation ensures that the entire window system works together to maximize sound insulation. This includes proper weatherstripping, adequate sealing, and appropriate mounting techniques that prevent vibration transmission through the building structure.

Environmental Factors and Placement

The orientation and placement of insulating glass windows should take into account local noise sources and environmental conditions. In urban settings, windows facing busy streets may require higher-performance configurations than those on quieter facades. Consideration should also be given to potential future changes in the surrounding environment that might affect noise levels.

Climate conditions can impact the long-term performance of insulating glass units. Proper drainage, ventilation, and maintenance are essential to prevent moisture accumulation and ensure continued acoustic effectiveness throughout the product's lifespan.

Cost-Benefit Analysis

Initial Investment Considerations

While insulating glass represents a higher initial investment compared to single-pane alternatives, its multiple benefits often justify the cost. The combination of noise reduction, energy efficiency, and improved comfort creates value that extends beyond simple monetary calculations. Property owners typically find that the enhanced living or working environment leads to increased property values and tenant satisfaction.

When evaluating costs, it's important to consider the long-term durability of modern insulating glass units. Quality products can maintain their acoustic and thermal performance for decades, making them a sound investment in building improvement.

Long-Term Value and Energy Savings

The dual benefits of sound insulation and energy efficiency make insulating glass particularly attractive from a long-term perspective. Reduced heating and cooling costs combine with improved acoustic comfort to create ongoing value. In commercial settings, the improved indoor environment can lead to increased productivity and better employee satisfaction.

Studies have shown that buildings with effective noise control through insulating glass tend to maintain higher occupancy rates and command premium rents, particularly in urban areas where external noise is a significant concern.

Frequently Asked Questions

How much noise reduction can I expect from insulating glass?

Quality insulating glass installations typically reduce external noise levels by 30-40 decibels, depending on the specific configuration and installation quality. This can reduce loud street noise to a comfortable background level in most situations.

Does the thickness of insulating glass affect its noise reduction capabilities?

Yes, the thickness of both glass panes and their asymmetrical configuration can significantly impact noise reduction performance. Different thicknesses are more effective at blocking specific sound frequencies, and manufacturers can optimize these parameters for particular applications.

How long does insulating glass maintain its noise reduction properties?

When properly installed and maintained, insulating glass units can maintain their acoustic performance for 20-30 years or more. Regular inspection of seals and frames helps ensure continued effectiveness throughout the product's lifespan.