The modern architectural landscape has witnessed a remarkable transformation with the integration of decorative glass panels as essential design elements. These versatile components have revolutionized how designers and architects approach both interior and exterior applications, offering unparalleled aesthetic appeal while maintaining functional integrity. Decorative glass panels serve as sophisticated solutions that bridge the gap between artistry and practicality, creating spaces that inspire and captivate while delivering superior performance characteristics.

Contemporary construction projects increasingly demand materials that combine visual sophistication with structural reliability. The evolution of glass manufacturing technology has enabled the production of decorative glass panels that exceed traditional expectations, incorporating advanced safety features and enhanced durability. These innovations have positioned decorative glass panels as preferred choices for architects seeking to create distinctive environments that stand the test of time.

Understanding the Technical Excellence of Modern Decorative Glass

Advanced Manufacturing Processes

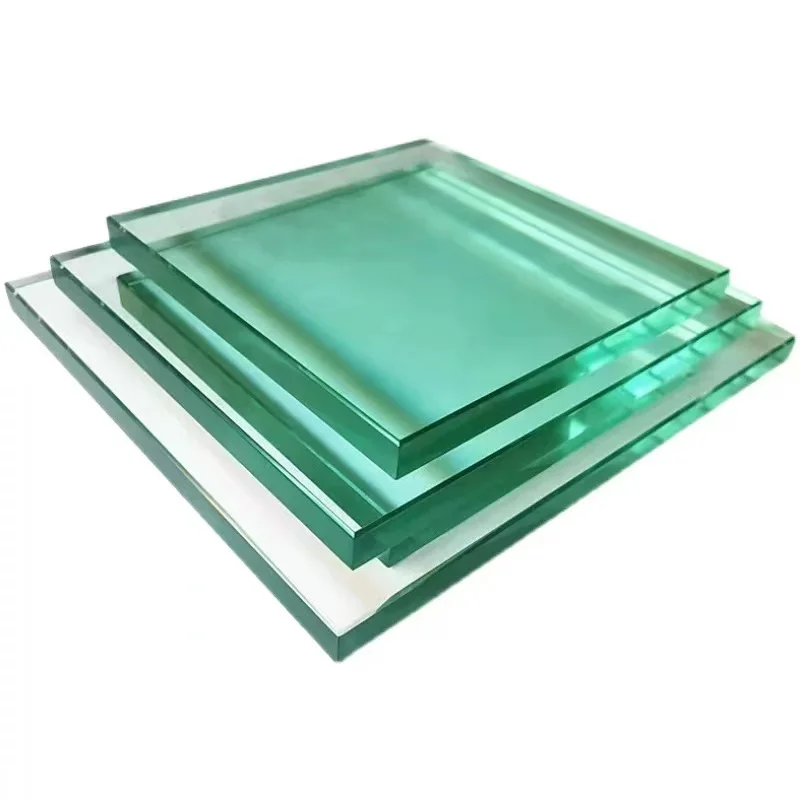

The creation of high-quality decorative glass panels involves sophisticated manufacturing techniques that ensure consistent quality and performance. Laminated tempering processes combine multiple glass layers with specialized interlayers, creating products that maintain structural integrity even under extreme conditions. These manufacturing methods enable decorative glass panels to achieve remarkable strength-to-weight ratios while preserving their aesthetic characteristics.

Quality control measures throughout the production cycle guarantee that each panel meets stringent industry standards. Advanced testing protocols evaluate impact resistance, thermal performance, and optical clarity to ensure decorative glass panels deliver reliable service across diverse applications. The integration of automated quality systems minimizes variations and maintains consistency across large-scale production runs.

Safety and Performance Standards

Contemporary decorative glass panels incorporate multiple safety features designed to protect occupants and maintain structural integrity. Tempered glass components undergo specialized heat treatment processes that create surface compression, resulting in panels that resist breakage and fragment safely when damaged. These safety characteristics make decorative glass panels suitable for high-traffic environments and critical applications.

Laminated construction methods further enhance safety performance by incorporating polymer interlayers that retain glass fragments upon impact. This design approach ensures that decorative glass panels maintain their protective function while delivering exceptional visual appeal. The combination of tempering and lamination creates products that exceed standard safety requirements while offering design flexibility.

Diverse Applications Across Architectural Contexts

Interior Design Solutions

Interior applications of decorative glass panels encompass a wide range of functional and aesthetic purposes. Wall cladding systems utilize these panels to create sophisticated surfaces that reflect light and enhance spatial perception. The transparency and translucency options available in decorative glass panels allow designers to manipulate natural light distribution while maintaining visual connectivity between spaces.

Partition systems incorporating decorative glass panels provide spatial definition without creating visual barriers. These installations maintain open-plan concepts while offering acoustic separation and privacy control. The versatility of decorative glass panels enables custom configurations that accommodate specific functional requirements while preserving design continuity throughout interior environments.

Exterior Building Applications

Curtain wall systems represent one of the most prominent applications for decorative glass panels in contemporary architecture. These installations create continuous glass facades that maximize natural light penetration while providing weather protection and thermal performance. The structural capabilities of decorative glass panels enable spanning large openings while maintaining code compliance and energy efficiency standards.

Greenhouse construction projects benefit significantly from the optical and thermal properties of decorative glass panels. The controlled light transmission characteristics optimize growing conditions while providing protection from environmental factors. Specialized coatings and treatments enhance the performance of decorative glass panels in agricultural applications, supporting sustainable growing practices and improved crop yields.

Design Flexibility and Customization Options

Surface Treatments and Textures

The surface treatment options available for decorative glass panels provide unlimited design possibilities. Etching, sandblasting, and digital printing techniques create unique textures and patterns that complement architectural themes. These processes allow decorative glass panels to incorporate custom graphics, logos, or artistic elements while maintaining their structural properties.

Specialized coatings enhance both aesthetic and functional characteristics of decorative glass panels. Anti-reflective treatments reduce glare while maintaining transparency, making these panels ideal for display applications. Self-cleaning coatings minimize maintenance requirements while preserving the visual appeal of decorative glass panels in challenging environmental conditions.

Color and Opacity Variations

Modern manufacturing techniques enable the production of decorative glass panels in virtually unlimited color combinations. Interlayer tinting provides consistent coloration throughout the panel thickness while maintaining clarity and light transmission. These capabilities allow decorative glass panels to complement specific color schemes and branding requirements.

Graduated opacity options create dynamic visual effects while controlling privacy and light levels. Decorative glass panels can incorporate varying degrees of translucency within single installations, creating sophisticated lighting effects and visual interest. These design capabilities make decorative glass panels versatile solutions for complex architectural requirements.

Installation Considerations and Best Practices

Structural Support Systems

Proper installation of decorative glass panels requires careful consideration of structural support requirements. Load calculations must account for wind loads, seismic forces, and thermal expansion to ensure long-term performance. The design of mounting systems for decorative glass panels must accommodate these forces while maintaining aesthetic continuity.

Glazing systems for decorative glass panels incorporate specialized gaskets and sealants that provide weather protection while allowing thermal movement. These components must maintain flexibility over extended service periods while preserving the visual appeal of decorative glass panels. Quality installation practices ensure optimal performance and minimize maintenance requirements.

Environmental Factors

Climate considerations significantly impact the selection and installation of decorative glass panels. Thermal cycling, humidity fluctuations, and UV exposure affect material performance and longevity. Proper specification of decorative glass panels must account for local environmental conditions to ensure satisfactory service life.

Drainage design prevents water accumulation around decorative glass panels while maintaining weathertight installations. Condensation management strategies protect against moisture-related issues that could compromise performance or appearance. These environmental considerations ensure decorative glass panels maintain their intended function and aesthetic appeal throughout their service life.

Maintenance and Longevity Strategies

Cleaning and Care Protocols

Maintaining the appearance of decorative glass panels requires appropriate cleaning techniques and materials. Specialized cleaning solutions preserve surface treatments while removing environmental contaminants effectively. Regular maintenance schedules ensure decorative glass panels retain their optical clarity and aesthetic appeal over extended service periods.

Inspection protocols identify potential issues before they compromise the performance of decorative glass panels. Systematic evaluation of mounting hardware, sealants, and glass surfaces enables proactive maintenance that extends service life. These practices ensure decorative glass panels continue delivering their intended benefits while minimizing lifecycle costs.

Performance Monitoring

Long-term performance tracking provides valuable data on the behavior of decorative glass panels under actual service conditions. Monitoring systems can identify trends and patterns that inform maintenance schedules and replacement planning. This approach maximizes the value of decorative glass panels while ensuring continued performance.

Documentation of maintenance activities creates historical records that support warranty claims and performance analysis. Comprehensive records enable optimization of maintenance procedures for decorative glass panels while supporting future specification decisions. This systematic approach ensures optimal return on investment while maintaining aesthetic standards.

FAQ

What thickness options are available for decorative glass panels

Decorative glass panels are typically available in thicknesses ranging from 5mm to 25mm, with laminated versions extending up to 50mm or more depending on specific requirements. The optimal thickness depends on factors such as span requirements, wind loads, and safety considerations. Thicker decorative glass panels provide enhanced structural performance but may require additional support systems.

How do decorative glass panels perform in extreme weather conditions

High-quality decorative glass panels are engineered to withstand extreme weather conditions including high winds, temperature fluctuations, and precipitation. Tempered and laminated construction provides superior resistance to thermal stress and impact damage. Proper installation with appropriate support systems ensures decorative glass panels maintain performance throughout their design life even in challenging climates.

Can decorative glass panels be customized for specific architectural requirements

Yes, decorative glass panels offer extensive customization options including custom sizes, colors, textures, and performance characteristics. Manufacturers can incorporate specific design elements, logos, or patterns while maintaining structural integrity. Custom decorative glass panels can be engineered to meet unique performance requirements including enhanced security, acoustic properties, or specialized optical characteristics.

What safety certifications should decorative glass panels meet

Decorative glass panels should comply with relevant building codes and safety standards such as ANSI Z97.1, CPSC 16 CFR 1201, and international equivalents. These certifications ensure the panels meet impact resistance and safety glazing requirements. Quality manufacturers provide comprehensive testing documentation and certifications for their decorative glass panels to support code compliance and project specifications.