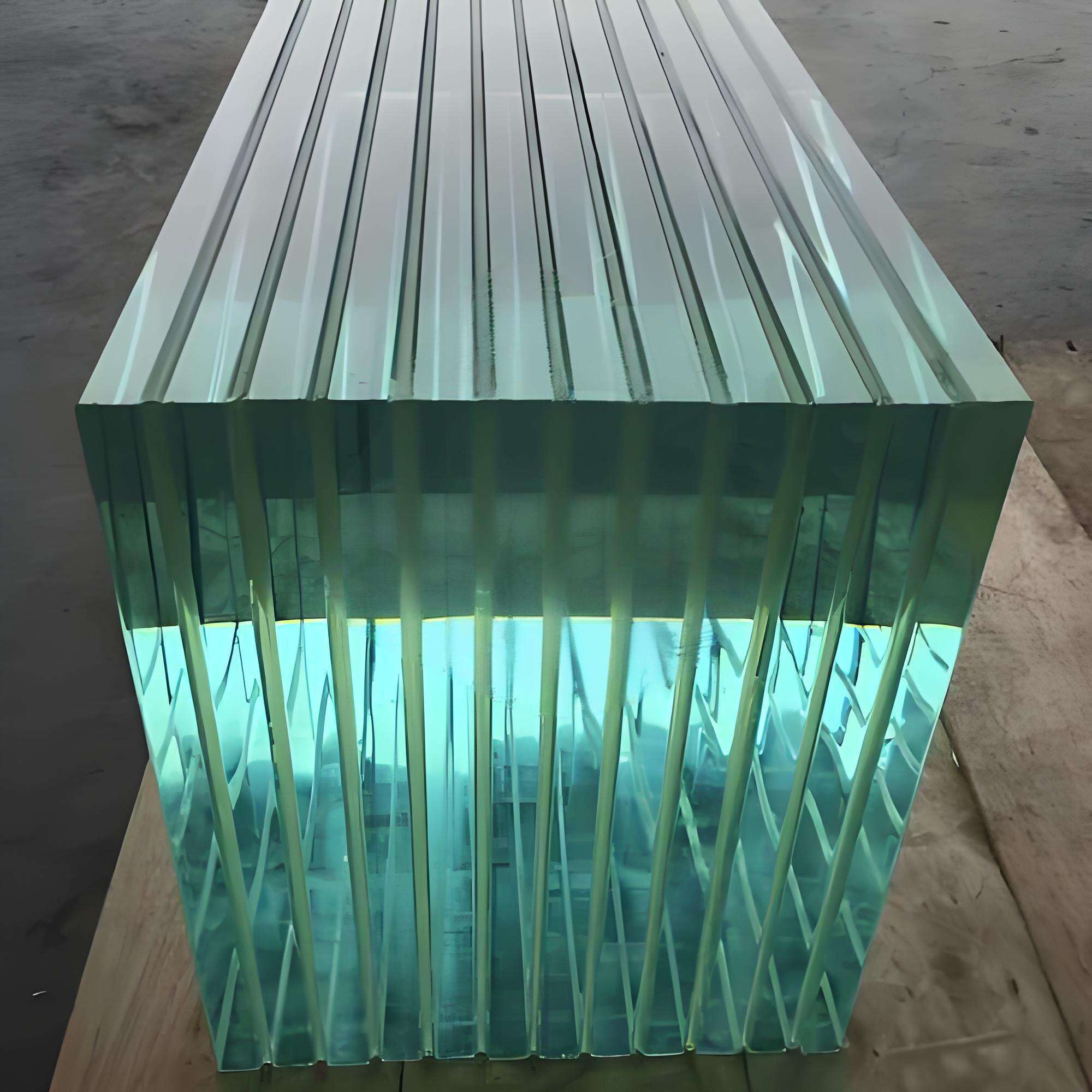

toughened laminated glass

Toughened laminated glass represents a significant advancement in glass technology, combining superior strength with enhanced safety features. This specialized glass consists of multiple layers bonded together with a high-strength interlayer, typically made from polyvinyl butyral (PVB) or ethylene-vinyl acetate (EVA). The manufacturing process involves heating the glass to near melting point and rapidly cooling it, creating a compression layer on the surface while maintaining tension in the center. This process results in glass that is up to five times stronger than standard glass. When broken, the glass remains adhered to the interlayer, preventing dangerous shards from scattering. The product finds extensive applications in architectural settings, automotive windshields, and high-security installations. Its multi-layered structure provides excellent sound insulation, UV protection, and resistance to impact. The glass can be customized in terms of thickness, size, and performance characteristics to meet specific project requirements. Modern variants can include additional features such as low-E coatings for energy efficiency or switchable privacy options. This versatile material has become increasingly popular in contemporary architecture, particularly in areas requiring both safety and aesthetic appeal.