Glass blocks have emerged as one of the most versatile building materials in modern architecture, combining exceptional durability with striking aesthetic appeal. These translucent structural elements offer architects and designers unprecedented flexibility in creating spaces that balance privacy, natural light transmission, and visual impact. From residential bathrooms to commercial facades, glass blocks continue to gain popularity due to their unique properties that traditional building materials simply cannot match.

Structural Integrity and Long-Term Performance

Exceptional Load-Bearing Capacity

The engineering behind glass blocks demonstrates remarkable structural capabilities that rival traditional masonry materials. These hollow glass units are manufactured using high-temperature fusion processes that create uniform wall thickness and eliminate weak points commonly found in other building materials. The inherent strength of glass blocks allows them to support significant loads while maintaining their transparency and aesthetic qualities over decades of use.

Manufacturing standards for glass blocks typically require compliance with strict structural codes, ensuring each unit can withstand compression forces exceeding 1,000 pounds per square inch. This impressive strength-to-weight ratio makes glass blocks particularly suitable for both load-bearing and non-load-bearing applications in residential and commercial construction projects.

Weather Resistance and Thermal Performance

Glass blocks exhibit superior resistance to environmental factors that commonly degrade other building materials. The non-porous surface prevents moisture infiltration, eliminating concerns about freeze-thaw damage, mold growth, or structural deterioration. This weather resistance extends the lifespan of glass blocks far beyond conventional alternatives, making them cost-effective investments for long-term construction projects.

The thermal properties of glass blocks contribute significantly to energy efficiency in modern buildings. The hollow design creates an insulating air gap that reduces heat transfer, while the glass composition allows for controlled light transmission without compromising thermal performance. These characteristics make glass blocks particularly valuable in climate-conscious construction where energy efficiency requirements continue to increase.

Design Versatility and Aesthetic Applications

Light Management and Privacy Solutions

One of the most compelling advantages of glass blocks lies in their ability to transmit natural light while maintaining privacy. The textured surfaces and internal patterns diffuse incoming light, creating soft, even illumination throughout interior spaces. This light-diffusing property eliminates harsh shadows and glare while preserving the connection between indoor and outdoor environments that occupants value.

Architects frequently specify glass blocks for applications requiring visual privacy without complete light blockage. Bathroom installations, partition walls, and security barriers benefit from this unique combination of transparency and discretion. The variety of available patterns and textures allows designers to customize light transmission levels according to specific project requirements.

Architectural Integration and Style Compatibility

Modern glass blocks complement diverse architectural styles, from contemporary minimalist designs to traditional residential renovations. The clean lines and geometric forms integrate seamlessly with current design trends while maintaining timeless appeal that prevents obsolescence. This versatility enables glass blocks to enhance both new construction projects and historic restoration efforts without compromising design integrity.

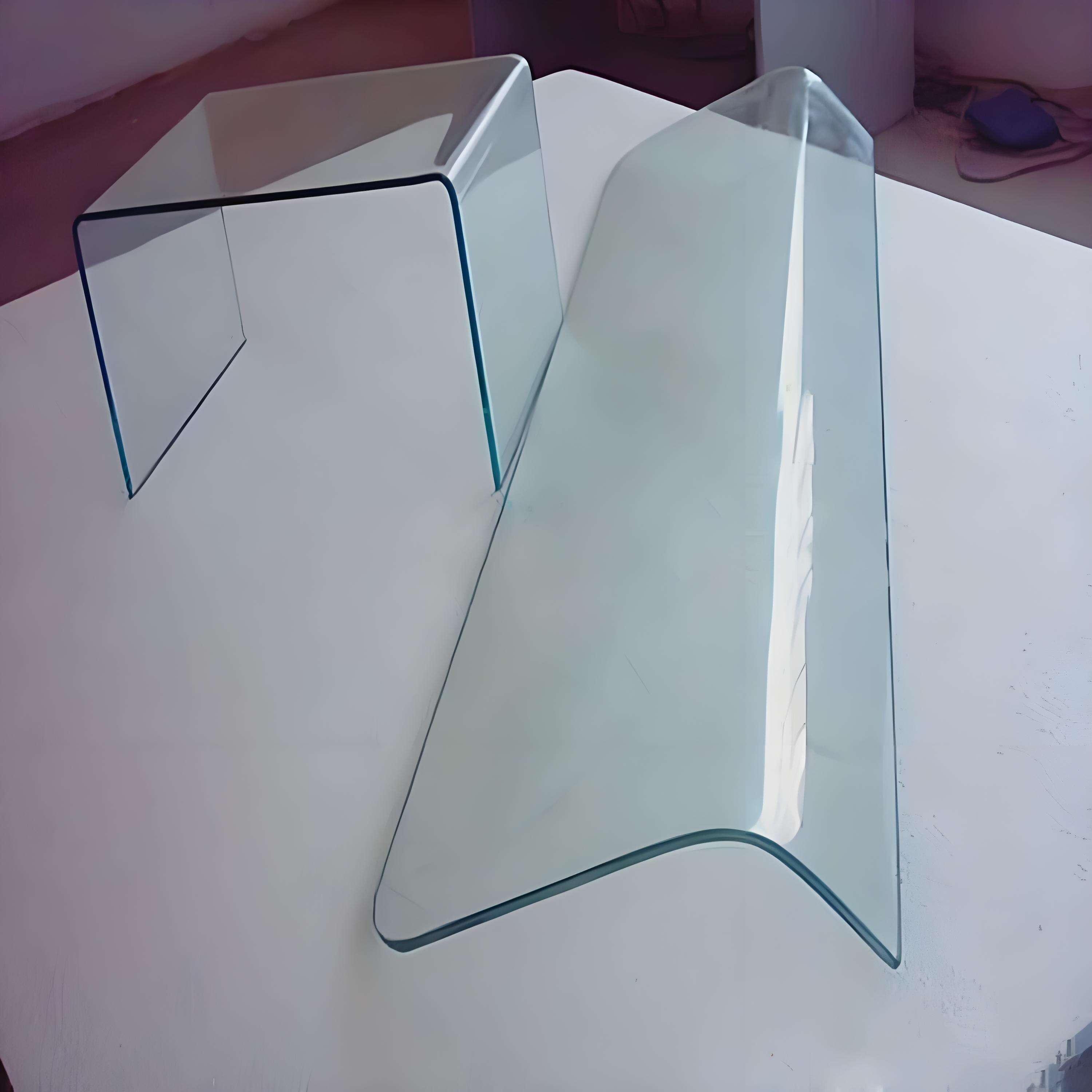

The availability of different sizes, shapes, and surface treatments expands creative possibilities for designers working with glass blocks. Curved units enable flowing architectural elements, while colored options provide accent features that enhance overall design concepts. These variations ensure that glass blocks can fulfill both functional requirements and aesthetic objectives within any architectural framework.

Installation Advantages and Construction Benefits

Simplified Installation Processes

Glass blocks offer significant installation advantages compared to traditional masonry materials. The standardized dimensions and interlocking design facilitate precise placement and alignment, reducing labor time and minimizing construction errors. Specialized mortars and reinforcement systems designed specifically for glass blocks ensure proper bonding and long-term stability without requiring extensive specialized training.

The relatively lightweight nature of glass blocks reduces structural loading requirements, potentially eliminating the need for additional foundation reinforcement in many applications. This weight advantage also simplifies handling and transportation during construction, contributing to overall project efficiency and cost control.

Maintenance Requirements and Lifecycle Costs

Long-term maintenance requirements for glass blocks remain minimal compared to other building materials. The non-porous glass surface resists staining, fading, and chemical deterioration, requiring only periodic cleaning to maintain optimal appearance. Unlike painted surfaces or natural stone, glass blocks do not require regular sealing, refinishing, or protective treatments throughout their service life.

The durability of glass blocks translates directly into favorable lifecycle cost calculations for building owners. While initial material costs may exceed some alternatives, the extended service life and minimal maintenance requirements typically result in lower total ownership costs over the building's lifespan. This economic advantage becomes particularly pronounced in harsh environmental conditions where other materials require frequent replacement or repair.

Technical Specifications and Performance Standards

Manufacturing Quality and Testing Protocols

Quality glass blocks undergo rigorous testing protocols that verify structural performance, thermal characteristics, and optical properties. These standardized tests ensure consistency across production batches and provide architects with reliable performance data for design calculations. Impact resistance testing, thermal cycling, and load-bearing evaluations confirm that glass blocks meet or exceed industry standards for construction materials.

The manufacturing process for premium glass blocks involves multiple quality checkpoints that eliminate defective units before distribution. Visual inspections identify surface imperfections, while dimensional measurements verify compliance with specified tolerances. These quality control measures ensure that each glass block meets the exacting standards required for successful architectural applications.

Code Compliance and Safety Considerations

Building codes increasingly recognize glass blocks as legitimate structural materials, with specific provisions addressing their use in various applications. Fire resistance ratings, structural load calculations, and safety glazing requirements have been established to guide proper specification and installation. These code provisions provide architects and contractors with clear guidelines for incorporating glass blocks into compliant building designs.

Safety considerations for glass blocks include impact resistance, emergency egress requirements, and seismic performance standards. Modern glass blocks are engineered to meet these safety criteria while maintaining their aesthetic and functional advantages. Proper installation techniques and appropriate reinforcement systems ensure that glass blocks contribute to overall building safety rather than compromising it.

Environmental Impact and Sustainability Benefits

Recycled Content and Manufacturing Efficiency

Contemporary glass blocks incorporate significant percentages of recycled glass content, reducing the environmental impact of new construction projects. The manufacturing process efficiently utilizes post-consumer and post-industrial glass waste, diverting materials from landfills while reducing raw material consumption. This recycling integration aligns with green building initiatives and sustainability certification programs that prioritize environmental responsibility.

Energy-efficient manufacturing processes minimize the carbon footprint associated with glass blocks production. Advanced furnace technologies and waste heat recovery systems reduce energy consumption during the melting and forming operations. These efficiency improvements make glass blocks increasingly attractive for environmentally conscious construction projects seeking to minimize their overall environmental impact.

Energy Performance and LEED Contributions

The thermal performance characteristics of glass blocks contribute positively to building energy efficiency ratings. The insulating properties reduce heating and cooling loads, while the light transmission capabilities minimize artificial lighting requirements during daylight hours. These energy benefits support LEED certification efforts and help buildings achieve increasingly stringent energy performance standards.

Daylighting strategies utilizing glass blocks can significantly reduce electrical energy consumption in commercial and institutional buildings. The controlled light transmission eliminates the need for electric lighting during most daylight hours while preventing glare and heat gain that could increase cooling loads. This balanced approach to natural lighting makes glass blocks valuable components in high-performance building designs.

FAQ

How long do glass blocks typically last in exterior applications?

Glass blocks in exterior applications typically last 50 years or more with minimal maintenance requirements. The non-porous glass surface resists weathering, UV degradation, and thermal cycling that commonly affect other building materials. Proper installation with appropriate mortar and reinforcement systems ensures long-term structural integrity and aesthetic appeal throughout the building's service life.

Can glass blocks provide adequate insulation for energy-efficient construction?

Yes, glass blocks offer excellent insulation properties due to their hollow design and thermal break characteristics. The air space within each unit provides insulation values comparable to double-pane windows, while the glass walls minimize thermal bridging. Many glass blocks exceed energy code requirements for thermal performance, making them suitable for high-efficiency building designs and green construction projects.

Are glass blocks suitable for load-bearing structural applications?

Glass blocks can function as load-bearing elements when properly designed and installed according to structural engineering requirements. The compression strength of quality glass blocks exceeds 1,000 psi, allowing them to support significant loads in both residential and commercial applications. However, structural calculations and appropriate reinforcement systems are essential for load-bearing installations to ensure code compliance and long-term performance.

What maintenance is required to keep glass blocks looking their best?

Glass blocks require minimal maintenance beyond periodic cleaning with standard glass cleaning products. The smooth, non-porous surface prevents dirt accumulation and staining, while the durable glass composition resists fading and chemical damage. Unlike other building materials, glass blocks do not require painting, sealing, or protective treatments, making them exceptionally low-maintenance architectural elements.