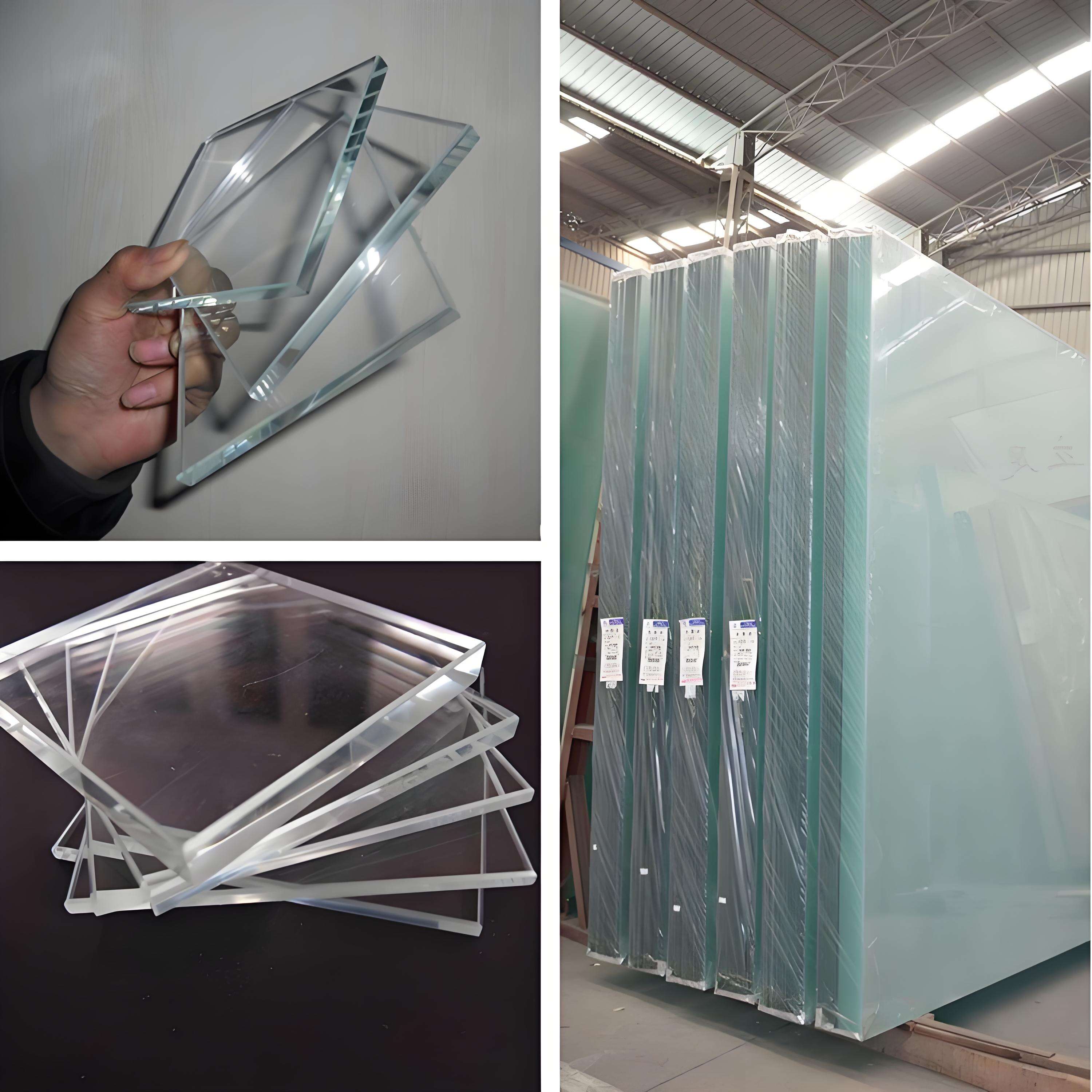

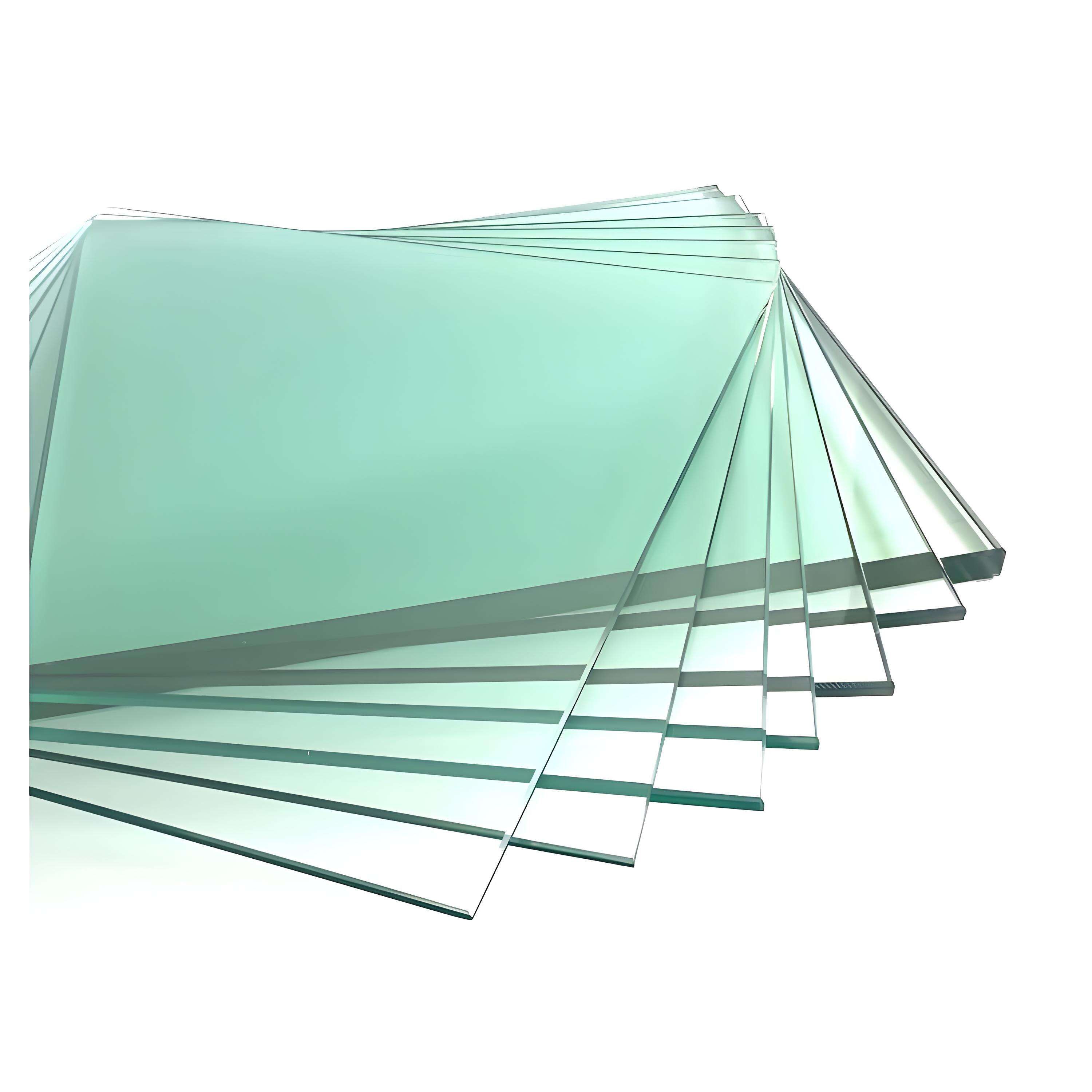

float glass supplier

A float glass supplier serves as a crucial partner in the architectural and manufacturing industries, providing high-quality glass products through an advanced float glass production process. This innovative method, developed by Pilkington in the 1950s, creates perfectly flat, distortion-free glass by floating molten glass on a bed of molten tin. The supplier maintains strict quality control measures throughout the production process, ensuring consistency in thickness, clarity, and structural integrity. Modern float glass suppliers utilize state-of-the-art technology to produce glass sheets ranging from 2mm to 19mm in thickness, suitable for various applications including commercial buildings, residential construction, automotive manufacturing, and solar panel production. They typically offer a comprehensive range of products, including clear float glass, tinted glass, reflective glass, and low-E glass, each engineered to meet specific performance requirements. These suppliers also provide value-added services such as cutting, tempering, laminating, and coating applications, allowing customers to receive customized glass solutions that meet their exact specifications. The supplier's role extends beyond mere production to include technical consultation, logistics management, and after-sales support, ensuring clients receive the most appropriate glass solutions for their projects.