float glass centre

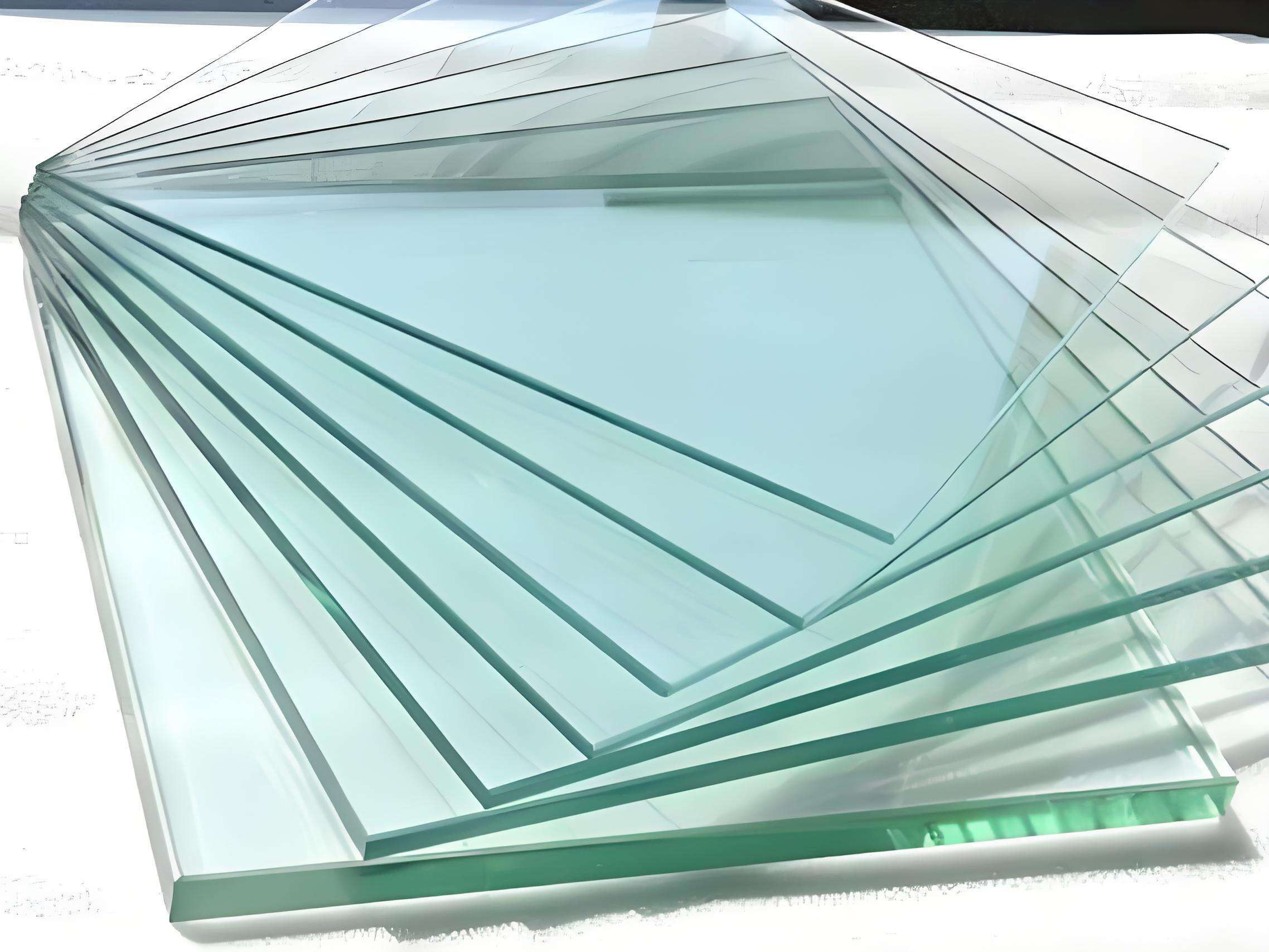

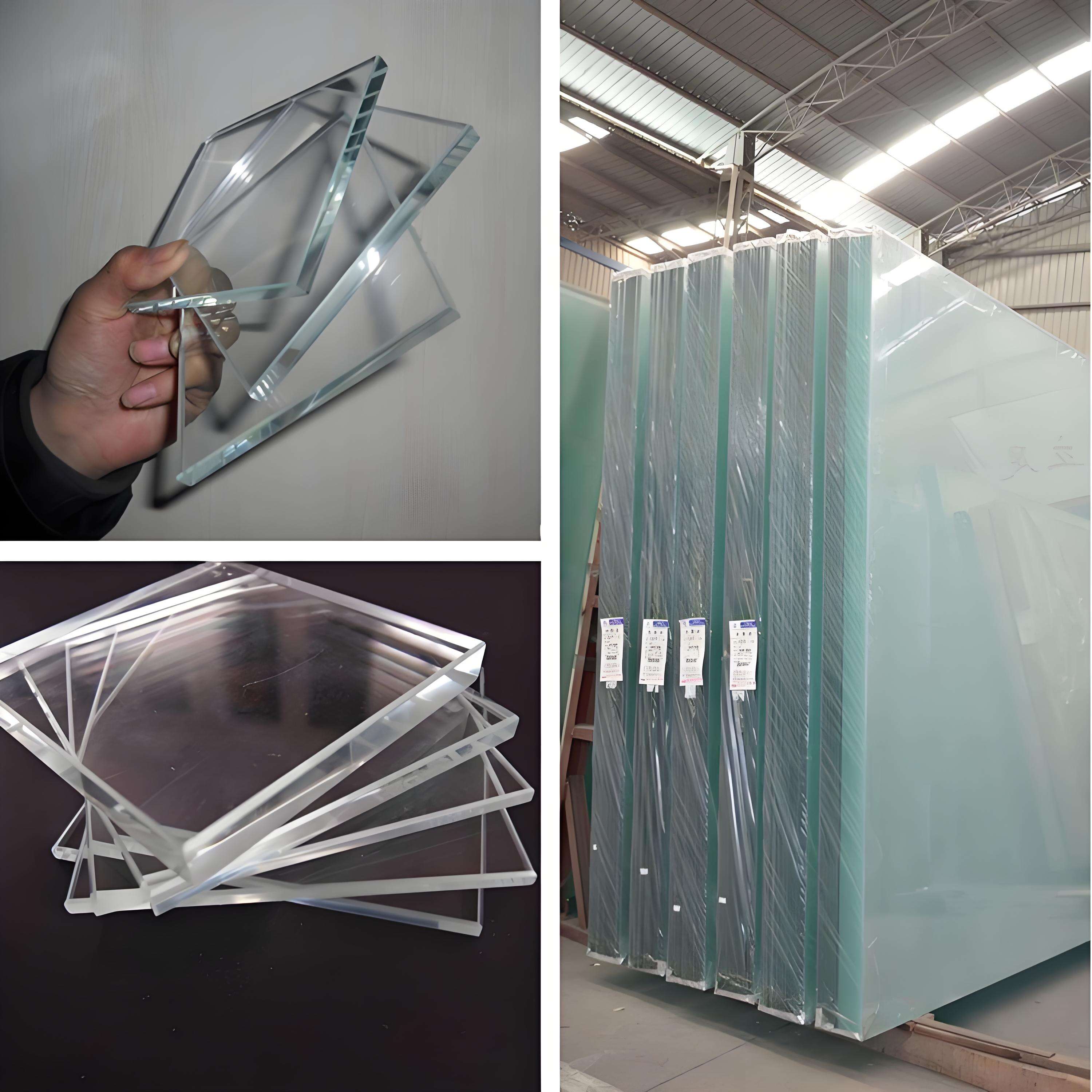

A float glass centre represents a state-of-the-art facility dedicated to the production and processing of high-quality glass products using the innovative float glass manufacturing method. This advanced facility combines cutting-edge technology with precision engineering to create perfectly flat, distortion-free glass sheets of varying thicknesses. The centre utilizes a sophisticated float bath process where molten glass flows over a bed of molten tin, creating an incredibly smooth surface on both sides. The facility incorporates automated quality control systems that monitor the entire production process, ensuring consistent excellence in every sheet produced. Modern float glass centres are equipped with advanced thermal control systems, automated cutting equipment, and sophisticated handling mechanisms that minimize human intervention while maximizing production efficiency. These facilities can produce glass sheets in various specifications, from ultra-thin panels for electronic displays to thick, tempered glass for architectural applications. The centre also features specialized coating chambers where various functional layers can be applied to enhance the glass properties, such as solar control, thermal insulation, or self-cleaning capabilities. With integrated logistics systems and storage solutions, these centres ensure proper handling and distribution of finished products while maintaining optimal inventory levels.