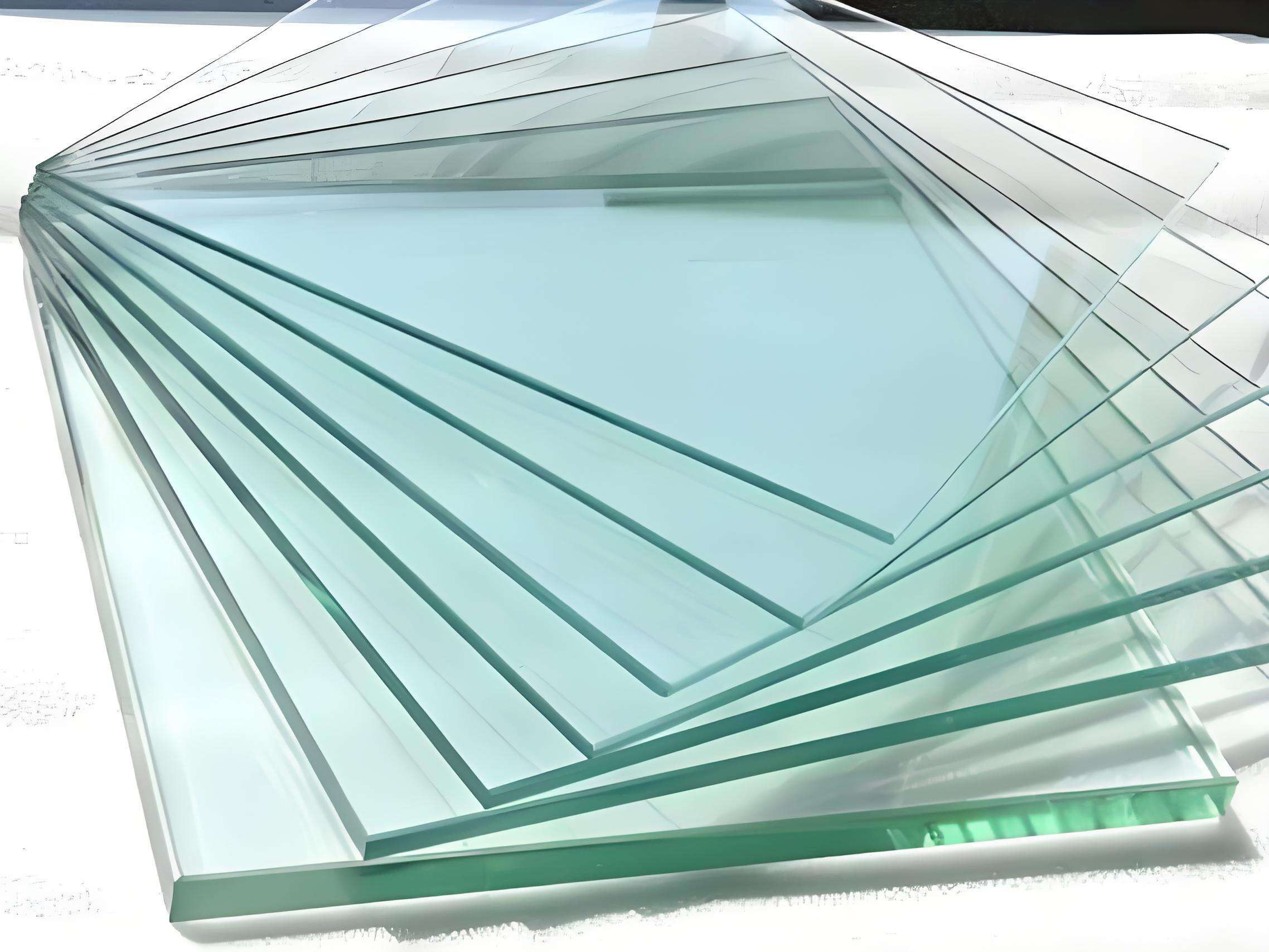

low iron glass tempered

Low iron glass tempered is a premium glass product that combines exceptional clarity with superior strength. This specialized glass is manufactured using high-quality silica with minimal iron content, typically containing less than 0.01% iron oxide, compared to standard glass which contains about 0.1%. The reduced iron content eliminates the characteristic green tint found in regular glass, resulting in remarkably clear and colorless appearance. Through the tempering process, the glass undergoes controlled thermal treatment, where it is heated to approximately 620°C and then rapidly cooled, creating a glass that is four to five times stronger than annealed glass. This process also ensures that if breakage occurs, the glass shatters into small, rounded pieces rather than sharp shards, making it a safer option. The enhanced clarity of low iron tempered glass makes it ideal for applications where visual precision and light transmission are crucial, such as solar panels, high-end architectural projects, display cases, and luxury residential windows. The combination of strength and clarity has made this product increasingly popular in modern construction and design, particularly in situations where both safety and aesthetics are paramount considerations.